Products

4 stiffener main axle neck structure, and it reach 560mm with the guide rail contact breadth, the rigidity is undeniable.

Z-axis using the 4 roller guide design, cutting more stable and more powerful!

Wide Rib

A body formed saddle place, it guaranteed that is fast and steady.

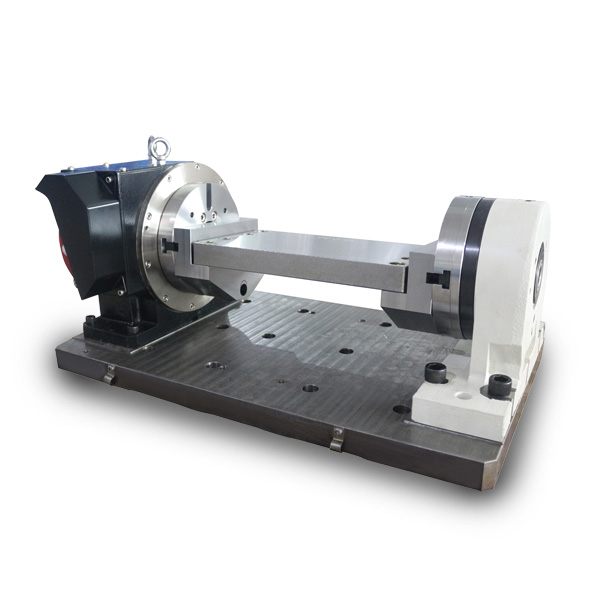

Optional with 4th and 5th axis

The work table designed with 5pcs T-slots, the components loading and unloading even better.

The column stiffener enable the machine to have the super high rigidity, and guaranteed that the time of heavy cutting has anti-distortion strength and extremely good attracts shakes ability, it lets you feel true intrepid.

The motor seat, the bearing seat and the fuselage conjoined, stability score body is improved by more than three times, the Z axis is used a roller guide.

Examples of processing products

Automotive parts

Aerospace parts

DDR/DDRT 4th-axis optional

DDR 4th-axis

DDRT 4th-axis

Specifications

| Model | CL700 | CL800 | CL1000 |

| Work table area | 840 x 400mm | 900 x 500mm | 1100 x 500mm |

| T slot(size x width) | 5 x 18mm | 5 x 18mm | 5 x 18mm |

| Max. table load | 350kg | 500kg | 600kg |

| 3 axis travel (X / Y / Z)) | 700/400/450mm | 800/600/500mm | 1000/600/500mm |

| Distance from spindle nose to table surface | 150 – 600mm | 120 – 620mm | 120 – 620mm |

| Distance from spindle center to machine column | 655mm | 655mm | 660mm |

| Spindle taper | BT40 | BT40 | BT40 |

| Max. spindle speed | 12,000rpm | 12,000rpm | 12,000rpm |

| Spindle driving type | Direct | Direct | Direct |

| Cutting feed | 12m/min | 12m/min | 12m/min |

| Rapid speed of X/Y/Z axis | 48/48/48m/min | 48/48/48m/min | 48m/min |

| Tool handle type | BT40 | BT40 | BT40 |

| Tool holder magazine capacity | 24tools | 24tools | 24 tools |

| Spindle power | 5.5kw | 11kw | 11kw |

| Servo motor of X.Y.Z axis | 1.3 x 2.0 x 2.9mm | 2.0 x 2.0 x 2.9mm | 2 x 2 x4.4kw |

| Machine size(L xWxH) | 2115 x 2255 x 2250mm | 2455 x 3000 x 2568mm | 2655 x 3000 x 2568mm |

| Machine weight | 3500kg | 5100kg | 5600kg |

| Positioning precision | ±0.005/300mm | ±0.005/300mm | ±0.005/300mm |

| Repeating positioning precision | ±0.003mm | ±0.003mm | ±0.003mm |

| Power requirement | 15KVA | 20KVA | 25KVA |

| Air pressure | 6-8Kgs/cm² | 6-8Kgs/cm² | 6-8Kgs/cm² |