Products

CNC Machining Centers, CNC Milling Machine Tools; CNC Vertical Machine Tools

Why CNC machines tools center/CNC machining tools center of Wise Hi Tech Industrial

Why CNC machining tools/CNC Machining Centers/CNC Milling Machines; CNC Machine Tools of Wise Hi Tech Industrial

Owns over 20 years experiences in Machining spare parts and components

Metal/Non-metal machining spare parts & components in processing from industrial fields by metal die Molds, plastic injection die molding, precision machinery, electronic machinery, power & electric machinery, automotive & motorcycle industries, bicycle industry, medical instrument and electronic device….that over 20 years experiences by operate the 5 axis CNC machining tools/5 axes CNC Machining Centers/5 axis CNC Milling Machines; 5/4 axis CNC vertical machining center tools/3 axis CNC Machine Tools/CNC lathes machine/CNC turning center/CNC drilling machines/CNC tapping machines/CNC grinders….etc.

Double column CNC milling machines tool/Double column CNC machining tools center/Vertical drilling CNC machine tools-DCM-600_Wise Hi Tech CNC

Completely manufacture 5/4/3 axis CNC machining tools/CNC Machining Centers/CNC Milling Machines; CNC Machine Tools series, 3 axes CNC Machining Tools Center series, vertical machining center/ linear guide ways CNC Machine Tools Center series, Box ways CNC Machining Tools Center series, double column CNC Machining Tools Center series, CNC Tapping Machine Tools Center series and CNC drilling Machining Tools Center series, C type/Bridge CNC Machine Tools Center series,

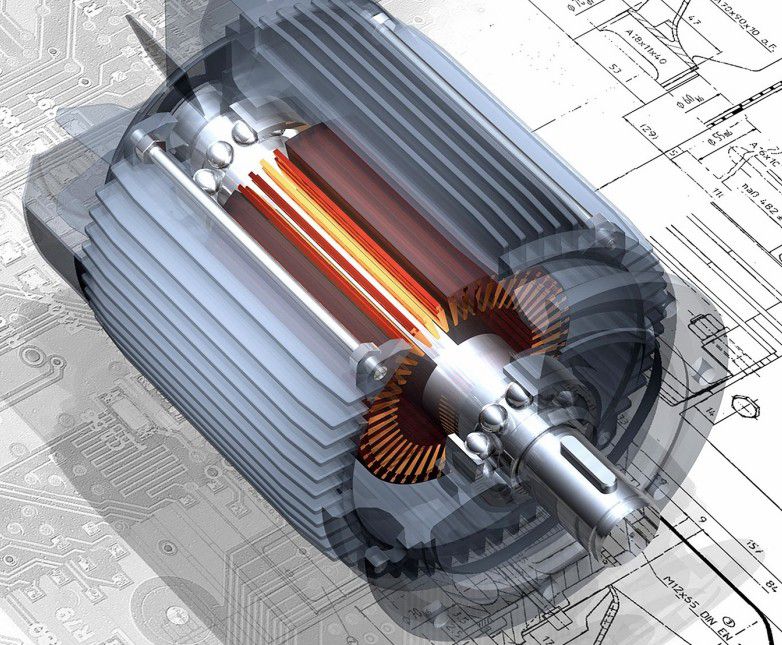

Advanced mechanical motor drive of double column CNC milling machines tools/Double column CNC drilling machining tools centers-DCM-600_Wise Hi Tech CNC

Performance machining of double column CNC Machining Centers/ double column CNC Milling Machines/ double column CNC machine tools

Advantages- double column CNC Machining Centers/ double column CNC Milling Machines/ double column CNC machine tools by VMC DCM-600

1) Combine big power/large torque/high efficiency/precise precision features.

2) Multiple coordinates linkage to machining the complex shape of working piece from spare parts & components.

3) Machine tool owns Strong rigidity/Structural symmetry/High stability for more efficient & top quality mass-production.

Double column machine cutters/Double column CNC machining toolings/Double column milling toolings/drilling cutter-DCM-600_Wise Hi Tech Industrial CNC

Specification – Double Column CNC machining tools/Double Column CNC Machining Centers/ Double Column Milling Machines by D. column_DCM-600

All specifications & design are subject to change without prior notice.

● : Standard accessories

△ : Depends on different or customized design

☆ : Optional accessories

| Guide Rail Type | X-Y-Z Roller type Linear Rail Ways |

Travels

| X - Axis | 600 mm |

| Y - Axis | 600 mm |

| Z - Axis | 400 mm |

| X / Y / Z Ballscrews | Ø32 x P8 mm |

| Spindle Nose to Table Surface | 150 - 550 mm |

| Distance Between 2 Columns | 600 mm |

Table

| Table Size | 600 x 600 mm |

| T - Slot ( Size/Qty./Dist. ) | 14 x 6 x 100 mm |

| Max. Load on Table | 600 kgs |

Spindle

| Spindle Speed | 24000 rpm |

| Taper | BBT-30 / HSK-40E |

| Spindle Drive | Built - In |

Motor

| Spindle Motor | 5.5 / 7.5 kw |

| X / Y / Z Motor ( Fanuc ) | 2 / 2 / 3 kw |

| X / Y / Z Motor ( Mitsubishi ) | 2 / 2 / 3 kw |

Feed Rates

| Rapid Feed Rate, X / Y / Z | 30 / 30 / 24 M/min |

| Cutting Feed Rate | 1~12 M/min |

ATC

| Tool Capacity | Armless / 16T pcs |

| Max. Tool Diameter | Ø100 mm |

| Max. Tool Length | 200 mm |

| Max. Tool Weight | 5 kgs |

Accuracy

| Positioning Accuracy | ±0.005 / 300 mm |

| Repeatability | ±0.003 mm |

Coolant

| Coolant Pressure | 50 - 80 psi |

| Coolant Tank Capacity | 200 liter |

Air & Power Supply

| Air Source | 6 - 8 kg/cm² |

| Power Supply | 15 KVA |

Machine

| Machine Size ( L x W x H ) | 230 x 243 x 265 cm |

| Packaging Size ( L x W x H ) | 230 x 240 x 255 cm |

| Machine Net Weight ( approx. ) | 5200 kgs |

| Machine Gross Weight ( approx. ) | 5600 kgs |

Standard Features

| Rigid Tapping | △ |

| RS-232 Interface | ● |

| Auto Power Off | ● |

| Auto Lubrication | ● |

| Work Light | ● |

| End of Program Light | ● |

| Heat Exchanger | ● |

| Full Guarding Enclosure | ● |

| Remote Hand wheel | ● |

| Screw Type Chip Conveyor | △ |

Optional Accessories

| Spindle Speed Upgraded to 12000rpm/Direct drive | ☆ |

| Spindle Speed Upgraded to 15000rpm/Direct drive | ☆ |

| Spindle Speed Upgraded to 24000rpm/Built-In | NIL |

| Coolant Through Spindle (CTS) | ☆ |

| Spindle Oil Cooler | ☆ |

| A/C for Elec. Cabinet | ☆ |

| 3-axes Optical Scale | ☆ |

| Chain Type Chip Conveyor | ☆ |

| Scraper Type Chip Conveyor | ☆ |

| Oil Skimmer | ☆ |

| Tool Length Measurement | ☆ |

| Spindle Coolant Splash | ☆ |

| Oil Mist Collector | ☆ |

| Transformer | ☆ |