Products

Owns over 20 years experiences in machining spare parts and components

Metal/Non-metal machining spare parts & components in processing from industrial fields by metal die molds, plastic injection die molding, precision machinery, electronic machinery, power & electric machinery, automotive & motorcycle industries, bicycle industry, medical instrument and electronic device….that over 20 years experiences by operating the 5 axis CNC machining tools/5 axes CNC Machining Centers/5 axis CNC Milling Machines; 5/4 axis CNC vertical machining center tools/3 axis CNC Machine Tools/CNC lathes machine/CNC turning center/CNC drilling machines/CNC tapping machines/CNC grinders….etc.

Completely manufacture 5/4/3 axis CNC machining tools/CNC Machining Centers/CNC Milling Machines; CNC Machine Tools series, 3 axes CNC Machining Tools Center series, vertical machining center/ linear guide ways CNC Machine Tools Center series, Box ways CNC Machining Tools Center series, double column CNC Machining Tools Center series, CNC Tapping Machine Tools Center series and CNC drilling Machining Tools Center series, C type/Bridge CNC Machine Tools Center series,

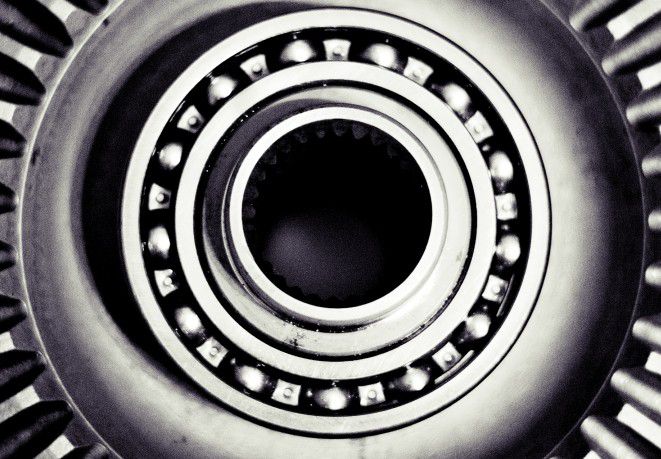

Industrial turbine/bearings parts machining by CNC lathes machine tools/CNC lathe machining tools center/CNC turning machining tools centers lathe

Performance Machining of CNC Lathe Machines/CNC Turning Machining Centers/ CNC Turning machine tools

Advantages- Machining of CNC Lathe Machines/CNC Turning Machining Centers/ CNC Turning machine tools by BDT-30B

The BDT-30B CNC lathe adopts an integrated body design. The low gravity bed can maintain the high rigidity of the whole machine. The center of the guide rail is symmetrical to the center point of the main shaft, which can reduce the deformation coefficient to a minimum. The machine maintains high performance even after long runs / cuts. The entire BDT series of CNC lathes can provide all different options according to the weight of the workpiece and its accuracy requirements.

The BDT-30B CNC lathe can use a servo turret for accurate positioning, and the turret mechanism can also be fixed by hydraulic screwing. Replacement of quick tools increases the productivity required by users and minimizes maintenance.

The best feature of the removable tailstock is that it can be carried around while the saddle is moving. The tailstock can also be fixed according to the size of the workpiece. Programmable tailstocks are also an alternative for users.

Industrial mechanic gears parts machining by CNC lathes machine tools/CNC lathe machining tools center/CNC turning machining tools centers lathe

Specification - Machining of CNC Lathe Machines/CNC Turning Machining Centers/ CNC Turning machine tools by BDT-30B