SIGMA CNC TECHNOLOGY MACHINERY CO., LTD.

Products

CNC gantry type machining center machinesCNC Double Column M

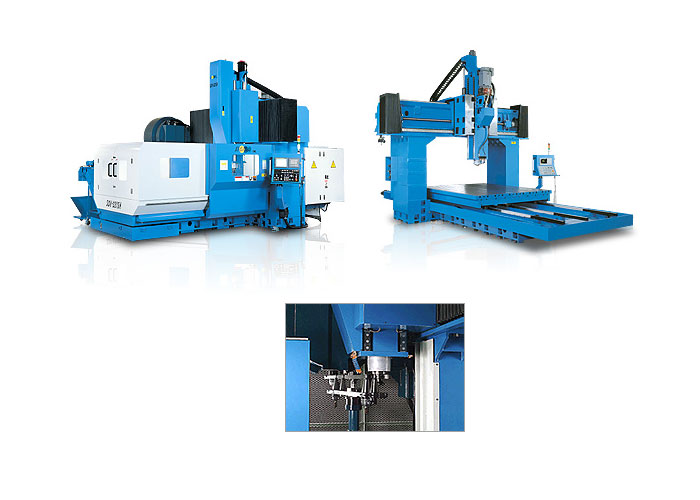

CNC Double Column Machining Center (SDV-H)

SDV-H

| ► SDV - 1611H, SDV - 2011H |

| ► SDV - 2215H, SDV - 2219H, SDV - 3215H |

| ► SDV - 3219H, SDV - 3224H |

| ► SDV - 4219H, SDV - 4224H |

| ► SDV - 5224H, SDV - 5229H |

Specification

Item / Model | Unit | SDV 1611H | SDV 2011H |

| X-axis Travel | mm | 1,600 | 2,040 |

| Y-axis Travel | mm | 1,100 | 1,100 |

| Z-axis Travel | mm | 760 | 760 |

| Table Size | mm | 1,600 x1,000 | 2,000 x1,000 |

| T-slots Dimension | mm | 22(24,28) | 22(24,28) |

| Table Load Capacity | kgs | 3,000 | 3,500 |

| Distance between Twe Columns | mm | 1,200 | 1,200 |

| Distance from Spindle Nose to Table | mm | 250~1,010 | |

| Spindle Taper, Tool Shank | ISO.NO50(40) BT-50, CAT-50, DIN 69871(BT-40, CAT-40), HSK-A63 | ||

| Spindle Speed Range | rpm | 20~4,000(30~6,000) (100~10,000) (80~8,000) (12,000~24,000) | |

| Main Motor Output (30 min Rating/Cont) | HP | 30/25(35/30) | |

| Rapid Traverse Rate X,Y Axis | mm/min | 15,000(20,000) | |

| Rapid Traverse Rate Z Axis | mm/min | 12,000(15,000) | |

| Cutting Feed Rate | mm/min | 1~5,000(1~8,000) | |

| Minimum Input Increment | mm/min | 0.001 | |

| Tool Magazine Capacity | pcs | (20/32/40) | |

| Max.Tool Diameter/ Adjacent Pockets Empty | mm | Ø 125/Ø210 | |

| Max. Tool Length (from Gauge Line) | mm | 350 | |

| Max. Tool Weight | kgs | (18/20) | |

| Tool Selection Method | ABS,Random Bi | ||

| Tool Change Time (T-T) (approx) | secs | 8(4.5) | |

| Power Requirement | Kva | 40(45) | |

| Floor Space Requirement | mm | 7,200 x 4,800 | 8,000 x 4,800 |

| Machine Height from Floor Level | mm | 4,355 | |

| Machine Weight (approx) | kgs | 20,000 | 20,500 |

| CNC Controller | Fanuc, Meldas, Siemens, Heldenhain series etc. | ||

| Positioning Accuracy | mm | JIS B6338 0.01/ 300 , VDI 3441 P0.025 | |

| Repeatability Accuracy | mm | ±0.003 | |

| STANDARD ACCESSORIES | |

| 1. LUBRICATION SYSTEM 2.GLAZED WINDOW-TYPE SPLASH GUARD 3.SCREW-TYPE CHIP CONVEYOR 4.LINK-TYPE CHIP CONVEYOR 5.COOLANT EQUIPMENT 6.SPINDLE OIL COOLER 7.Z-AXIS HYDRAULIC BALANCE UNIT 8.PNEUMATIC UNIT 9.AIR BLOW FOR CHIP(BY M-CODE) | 10.WORK LAMP 11.AUTO POWER-OFF SYSTEM 12.M.P.G 13.PROGRAM END&ALARM LAMP 14.RS-232 INTERFACE 15.LEVELING BLOCK AND BOLTS 16.TOOL KIT 17.MAINTENANCE AND OPERATION MANUAL 18.INSPECTION LIST |

| OPTIONAL ACCESSORIES | |

| 1.AUXILIARY TABLE 2.NC(ROTARY TABLE,INDEX TABLE) 3.16,20,32,40,60 A.T.C MAGAZINE CAPACITY 4.TOOL PRESETTER 5.AUTO TOOL LENGTH DIAMETER MEASUREMENT 6.AUTO TOUCH PROBE SYSTEM 7.LINEAR SCALE FEEDBACK 8.COOLANT THROUGH SPINDLE SYSTEM | 9.OIL HOLE TOOL SHANK DEVICE 10.COOLANT AUTO AIR MIST DEVICE 11.COOLANT NOZZLE ANGLE REMOTE CONTROL 12.MANUAL 45° 90° ANGLE HEAD, UNIVERSAL HEAD,EXTENSION HEAD 13.SPINDLE THERMAL COMPENSATION 14.AVAIABLE WITH DIFFERENT SPINDLE SPEC & RPM 15.(AAC) 90° ANGLE HEAD, SWING DIVIDED ANGLE HEAD INDEX IN C-AXIS (AVAILABLE 4,8,12,24,72 POSITION), EXTENSION HEAD (360,560 MM)(FOR SDV-H SERIES ONLY) 16.MANUAL FULL SPLASH GUARD |

Note:

1.( ) Description is optional accessories.

2.To research and improve our company keep the right of changing design and structure at

any time, this data is just for reference.