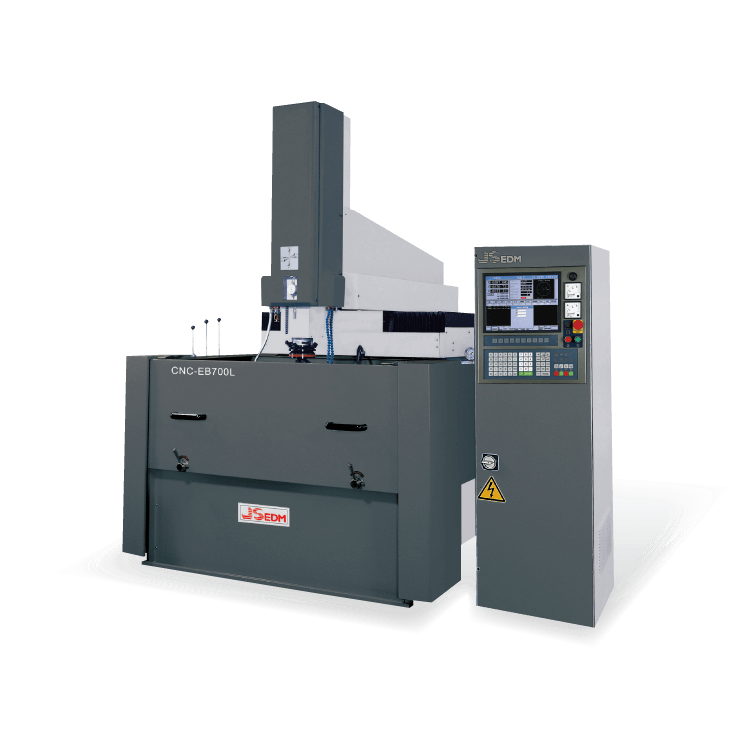

Products

User friendly industrial CNC controller

Industrial computer (IPC), with industrial CF card and support USB disk data copy backup function, so that the data is more convenient and reliable.

Chinese & English display.

Metric & British system display & program setting.

1,000 stations processing programs. Simplify the program editing; with one block command, you can finish line multi-cavity machining and matrix multi-cavity machining.

10 files, each with 256 sets of processing parameters table, which can store processing conditions.

Automatic Edge finding, Home finding, Center or Inner hole finding, and Apex finding.

The Conversation type program has Loop & Call, Note & Pause, Mark / Copy / Delete Block and Skip line functions. It is easier to learn, write, & edit programs.

Has Side loran function (X, Y axis), Angle Vector machining function, and ARC clockwise & ARC counter Clockwise function.

Single or 3 axis lateral machining, Round orbiting, Square orbiting, & Vector machining.

Optional accessories A.T.C., C Axis (Including the helical-gear machining, C-X / C-Y axis lateral rock machining, and other applied machining commands).

-

Capacity of Work Tank

1500x940x520 mm

-

Work Table Size

1000x600 mm

-

Longitudinal Travel (X-Axis)

600 mm

-

Cross Travel (Y-Axis)

450 mm

-

Z Axis Travel (Z-Axis)

400 mm

-

Distance Between Platen to Table

350~750 mm

-

Max. Electrode Weight

250 kgs

-

Max. Work Piece Weight

3000 kgs

-

Fluid Tank Capacity

1100 L

-

Machine Outside Dimensions (WxDxH)

2850x2700x2610 mm

-

Machine Weight

3600 kgs

-

Max. Machining Current

60 / 90 A (Optional)

-

Max. Power Input

7 / 10 KVA

-

Max. Machining Rate

400 / 600 mm3/min

-

Min. Electrode Wear Ratio

0.12 %

-

Best surface / Ra

Ra 0.2 μm

-

Min. D. R. O. Resolution

0.001 mm

-

Generator Weight

320 kgs