Products

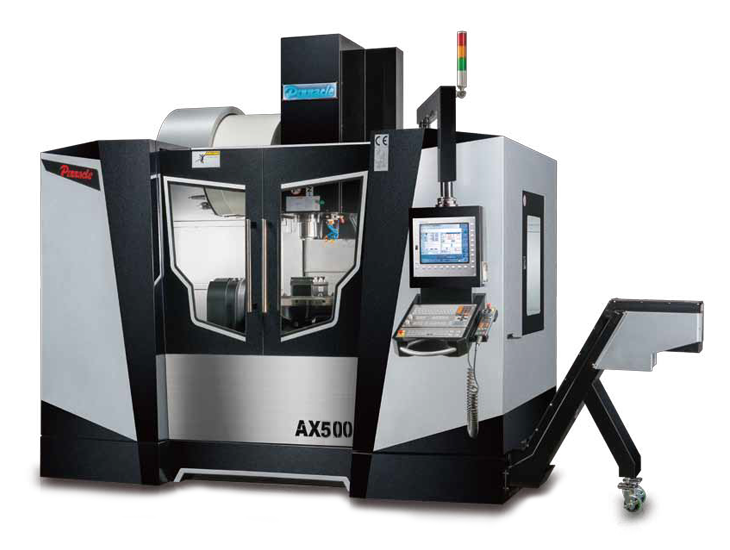

5 - AXIS MACHINING CENTER

The major structure parts are manufactured from high quality Meehanite cast iron, tempered for stress relief.

A/C adopt DD motor ensure the high accuracy and efficient.

The 5-axis synchronized machining saves machining time reduces repetitive workpiece setup and error,while dramatically increasing machining and accuracy.

Pinnacle AX170/ AX320/ AX450/ AX500 are proven to be super machines for high efficiency and accuracy.

Features

760 x 610 x 560 mm Travel

A Axis Tilt 220° (±110°)

C Axis Rotary 360°

Rapid Feedrate 30/30/24

9/12 Kw Spindle Motor

ISO40 Spindle Taper

X, Y & Z Axis Linear Way

Rigid, Stable, Accurate

RUGGEDLY CONSTRUCTED THROUGHOUT TO PROVTDE LIFETIME ACCURACY YEAR AFTER YEAR

The major structural parts are manufactured form high quality Meehanite cast iron (GB 300), tempered for stress relief with hardness over 190HB.

45mm Roller type linear ways on X, Y, Z axis increased stability.

X, Y, Z axis are transmitted with class C3, Ø40mm ball screws.

HIGH SPEED 5 AXES M/C

ISO40 15000rpm

HSKA63 24000rpm

Table size500MM

Heidenhain TNC640

COOLANT THROUGH BALL SCREW (STANDARD)

Coolant through ball screws on X, Y axis minimizes thermal deformation and backlash, while ensuring smooth motion during rapid traverse.

PNEUMATIC BALANCE SYSTEM

The Z-axis is pneumatic counter-balanced via high response pneumatic cylinders. Plus an air reservoir tank to boost the balancing performance, ensuring fast and stable Z-axis movement, giving high surface finish.

COOLING SYSTEM TO SPINDLE

The spindle oil cooler permits the spindle to keep a constant temperature running and ensures long service life. It also provides high efficiency machining and high accuracy.

| MODEL | AX500 |

|---|---|

| MOVE TYPE | Fix column |

| TABLE | |

| TABLE SIZE & NUMBER (mm) | Ø500 |

| TRAVEL RANGES (X/Y/Z mm) | 760 x 610 x 560 |

| SCREW SIZE (Size x Pitch mm) | 14 |

| MAX. TABLE LOAD (Kg) | 500 |

| MAX. WORKPIECE SIZE (WxH mm) | Ø500 x 350 |

| DIAMETER OF TABLE HOLE (mm) | Ø50 |

| SPINDLE NOSE TO TABLE SURFACE (mm) | 35~595 |

| A Axis, Tilt (deg)/(0.001°) | 220°(±110°) |

| C Axis, Rotary (deg)/(0.001°) | 360° |

| SPINDLE | |

| DISTANCE BETWEEN COLUMN (mm) | ISO40 |

| SPINDLE INNER DIAMETER (mm) | Ø70 |

| SPINDLE SPEED (rpm) Belt | - |

| SPINDLE SPEED (rpm) Direct drive | 10000 (12000/15000) |

| SPINDLE SPEED (rpm) Built-in | 20000 |

| MAIN MOTOR (con/30min kW) | 11 / 15 |

| THREE-AXIS MOTOR | |

| RAPID FEED RATE (X/Y/Z m/min) | 30/30/24 |

| FEED RATE (X/Y/Z m/min) | 10 |

| FEED RATE (A/C rev/min) D.D motor | 30/90 |

| X-Axis Rated Torque (Nm) | 10 |

| YAxis Rated Torque(Nm) | 10 |

| Z-Axis Rated Torque(Nm) | 10 |

| A-Axis Rated Torque(Nm) D.D motor | 1290 |

| C-Axis Rated Torque(Nm) D.D motor | 600 |

| ATC | |

| ATC TYPE | DISK(CHAIN) |

| CAM TYPE | ARM |

| TOOL SELECTION (Bi-direction) | RANDOM |

| TOOL STORAGE CAPACITY (PCs) | 24/30 (40) |

| MAX. TOOL DIAMETER (mm) | Ø90 (Ø76) |

| MAX. TOOL LENGTH | 250 |

| MAX. TOOL WEIGHT | 8 |

| MISCELLANEOUS | |

| AIR REQUIREMENT (Kg/cm2) | 6 |

| VOLTAGE | 380 |

| POWER REQUIREMENT (KVA) | 40 |

| COOLANT TANK CAPACITY (L) | 300 |

| MACHINE WEIGHT (KGs) | 7100 |

| MACHINE HEIGHT (mm) | 3280 |

| FLOOR SPACE (LxW mm) | 3100 x 2390 |

| PACKING SIZE (LxWxH mm) | 3150 x 2230 x 2560 |

All Specifications And Designs Are Subject To Change Without Notice.

WORK RANGE

SPINDLE POWER CHART

T-SLOTS