Products

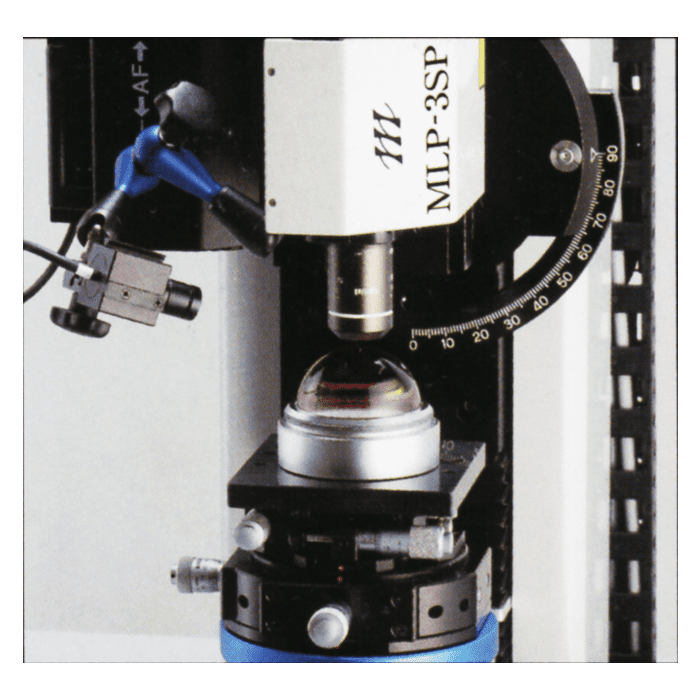

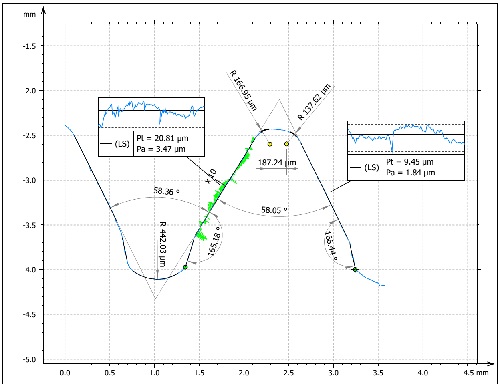

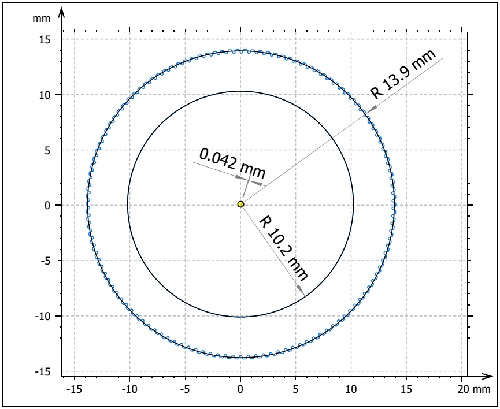

The 5-axis controlled movement of the full-circle contour measuring instrument is suitable for measuring samples with a measurement accuracy of less than 120mm and less than 1um. The measured groove profile is suitable for sample contour measurement of precision machining or ultra-precision machining. The measurement data can be 3D modeled to provide a reference for reverse engineering measurement.

_________________________________________________________________________________________________________________________________________________________________________

【 feature of product 】

* Minimum laser spot 1um (obj.x100)

* XYZ stage 120x120x130 mm

* AF (R): 40mm

* AZ return axis: 360 ゜

* XYZ analysis: 0.1x0.1x0.1um

* AF (R) analysis: 0.01um

* AZ analysis: 0.0002 ゜

【Applied Composite Materials】

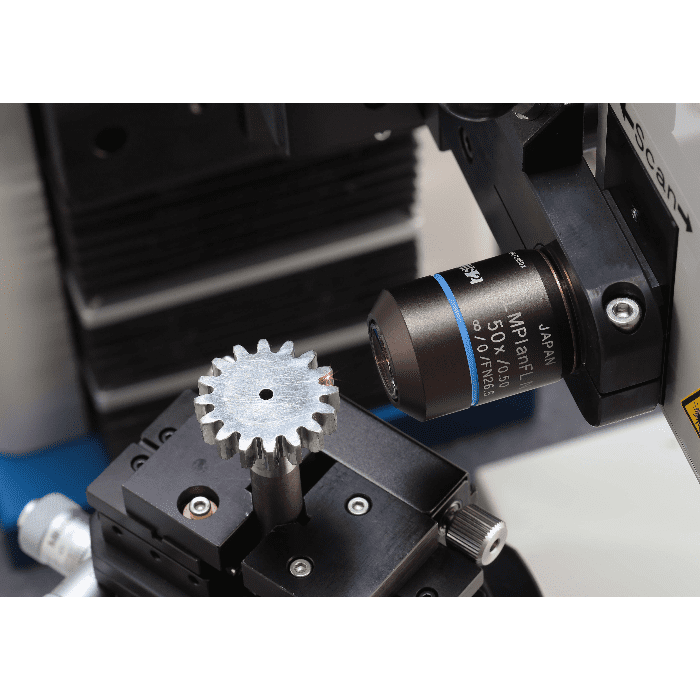

* Non-contact method, measuring gear profile, T gear modulus and shape thickness roughness involute gear, non-involute gear, spur gear, internal gear, bevel gear ... etc. Various gear measurements

* Non-contact measuring instrument capable of measuring gear modulus less than 0.5

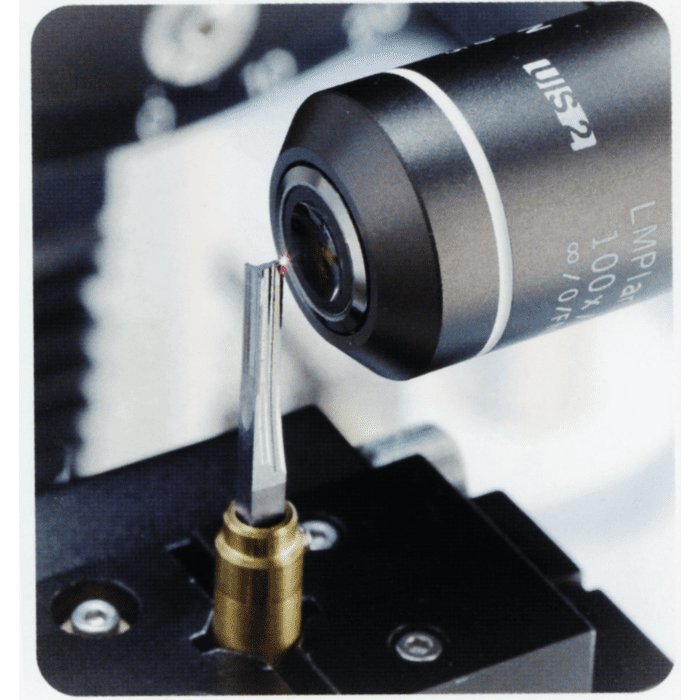

* The measurement parameters of the screw are provided: geometric profile, waviness, roughness, lead angle (helix angle),

* Soft materials, such as silicone rubber products

* Transparent materials, such as light guide plates, lenses, gem spheres

* Stamping materials: such as bearings, fasteners, precision die casting, precision injection molding

* Precision processing: such as precision screws, ball screws, precision slide rails, small modulus gears

Minimum laser spot 1um (obj.x100 NA0.95)

Long stroke working range (customizable)

XYZ stage 120x90x130 mm

AF (R): 40mm

AZ return axis: 360 ゜

XYZ analysis: 0.1x0.1x0.1um

AF (R) analysis: 0.01um

AZ analysis: 0.0002 ゜

齒輪齒型, 幾何輪廓及形狀粗度量測

齒輪內外徑同心度量測