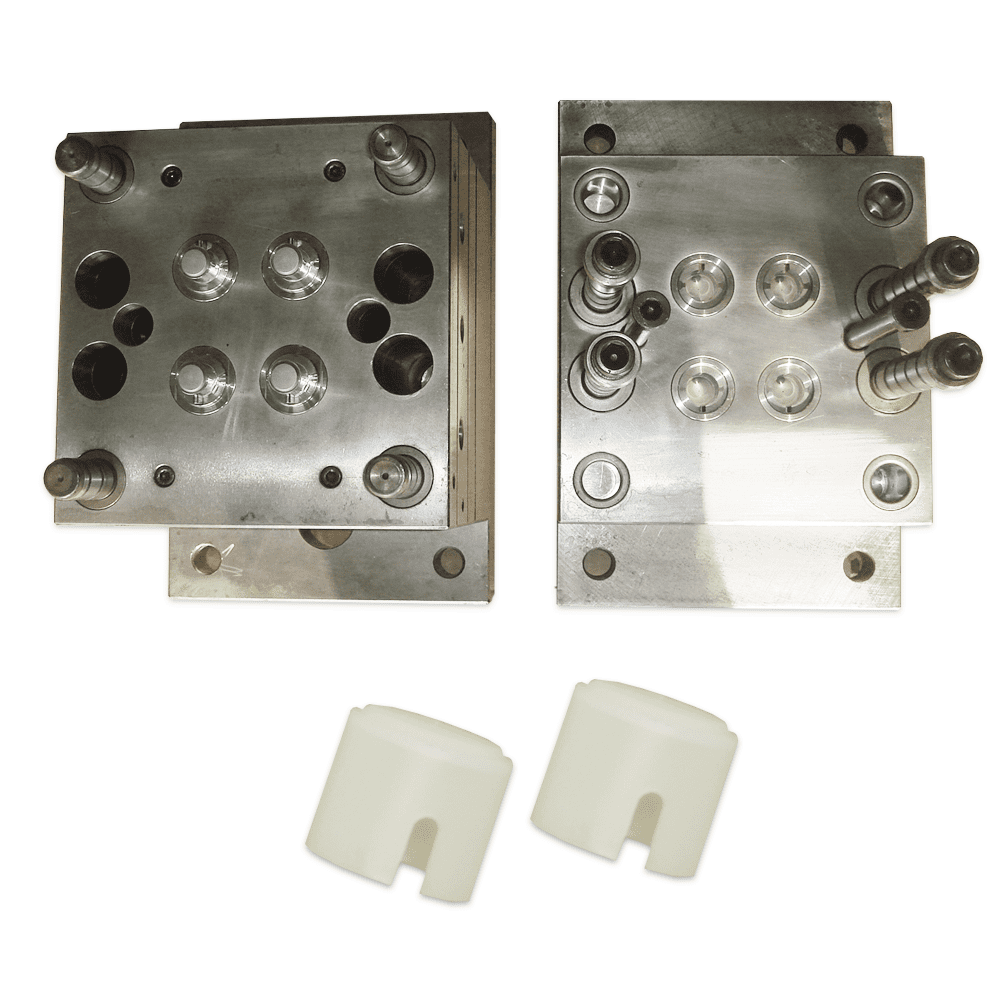

Products

1.Quality Assurance: The mold design and manufacturing process undergo rigorous quality control to ensure that each lipstick component meets high standards and quality.

2.Efficient Production: Injection mold technology enables efficient production of lipstick components, enhancing production line efficiency.

3.Customized Solutions: Lipstick component molds can be customized according to customer requirements to meet various shapes and specifications.

4.Durability: These molds are designed to be robust and durable, allowing for the long-term stable production of high-quality lipstick components, meeting the high standards of the cosmetics industry.

Product Highlights

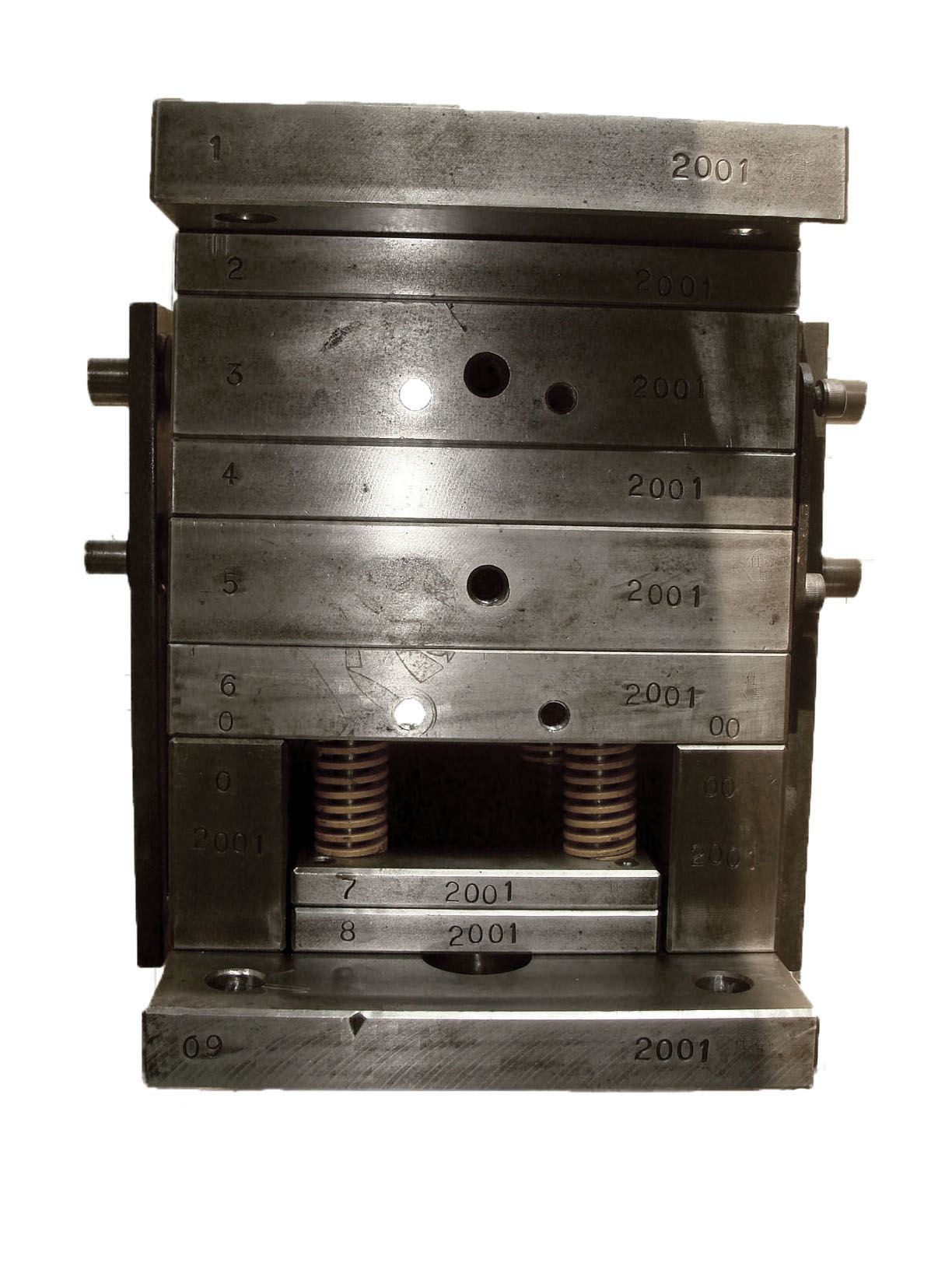

Plastic lipstick component molds stand out for their high precision and durability. Precision mold design ensures consistent sizing of lipstick components and increases production efficiency. Molds made from stainless steel and carbon steel provide a high lifecycle, meeting the demands of high-quality, high-capacity lipstick manufacturing while also offering customized ODM/OEM services.

| Material | stainless steel, carbon steel |

| Color | nickel white |

| Mould Base | LKM |

| Mould Base Material | S50C |

| Core Material | M310 |

| Cavity QTY | 4 cavities |

| Runner | cold runner |

| Gate | Submarine gate |

| Mould lifetime | 300,000~500,000 shots |

| Design software | UG, CAD |

| Mold flow software | Moldex 3D |

| Plastic part material | ABS |

| Mould dimension | Length : 295 Width : 400 Height : 200 mm |

| OEM and ODM | Acceptable |

| Packing | Wooden package or as your request |