Products

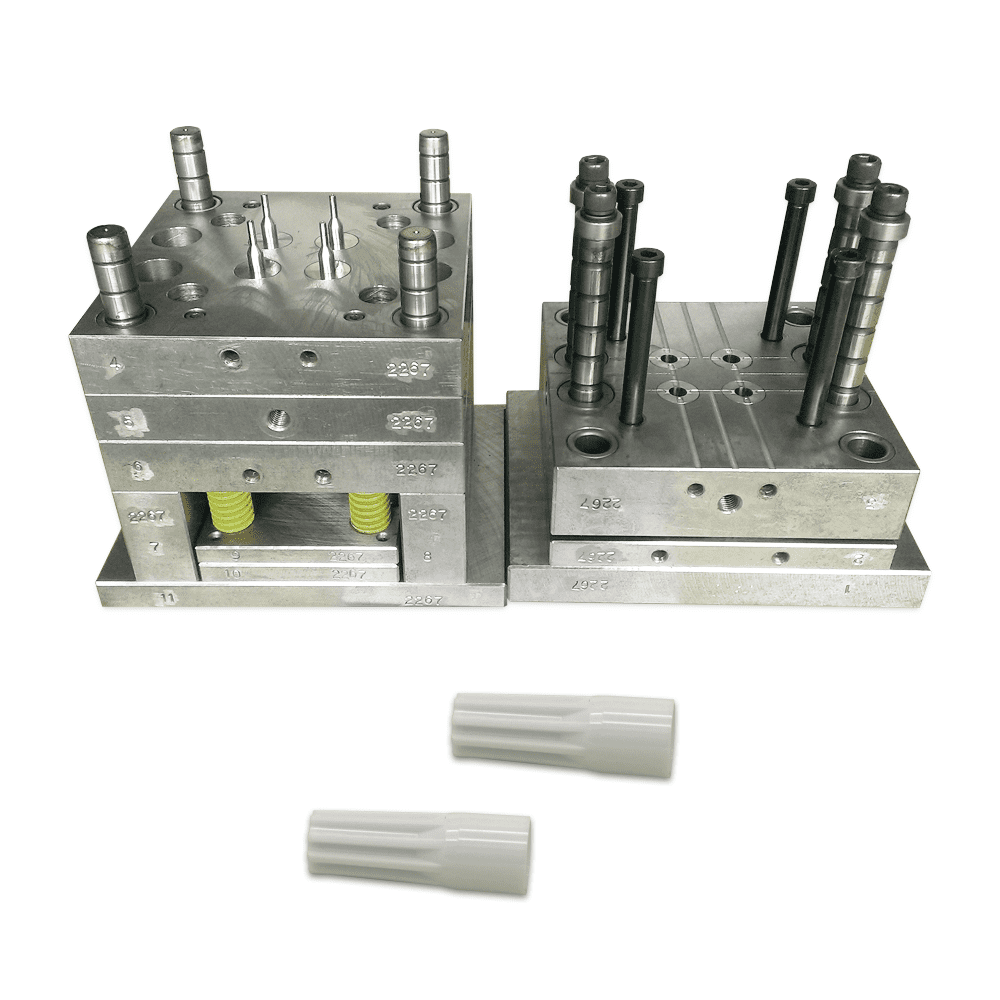

Regular mold maintenance and upkeep are crucial steps to ensure the long-term operation of pen cap molds. This includes cleaning, repairing damage, and replacing worn-out components. Chii Lee manufactures molds and conducts mass production with a focus on permanent maintenance.

Common materials and advantages include:

1.PBT, PP, ABS, AS

2.Smooth surface with injection points on the inside

3.Weather resistance

4.Impact resistance

Product Highlights

The plastic injection molding mold-making process for pen cap production typically includes the following steps:

1.Pen cap mold design

2.Mold production

3.Sample testing

4.Plastic heating

5.Injection molding

6.Finishing and inspection

With molds produced and molded at Chii Lee, we offer permanent maintenance without shifting blame or evading responsibility, providing you with peace of mind.

| Material | stainless steel, carbon steel |

| Color | nickel white |

| Mould Base | LKM |

| Mould Base Material | S50C |

| Core Material | M310 |

| Cavity QTY | 4 cavities |

| Runner | cold runner |

| Gate | Submarine gate |

| Mould lifetime | 300,000~500,000 shots |

| Design software | UG, CAD |

| Mold flow software | Moldex 3D |

| Plastic part material | ABS |

| Mould dimension | Length : 295 Width : 400 Height : 200 mm |

| OEM and ODM | Acceptable |

| Packing | Wooden package or as your request |