Products

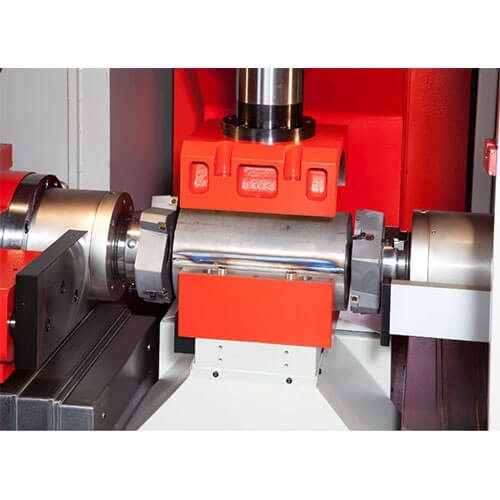

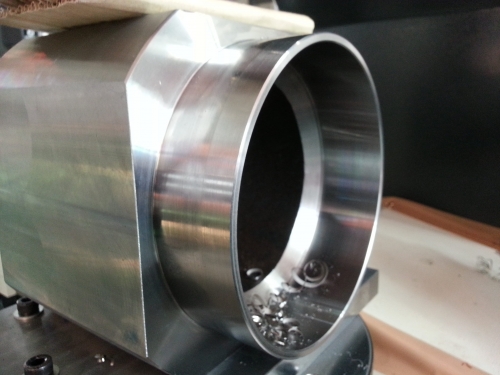

NC-400i is a special designed machine for machining the round tube workpiece. NC-400i can mill the both sides of workpiece at the same time by using the powerful milling heads and the automatic operation process is the most advantage of this machine.\

STANDARD FEATURES

One-piece rigid construction machine base.

Cutting spindle (NT50) X and Y-axis.

Spindle guides are TURCITE-B coated and precision scraped.

3 axes control, X, Y, and Z axes (L, R cutting spindle and worktable)。

Vertical clamp hydraulic cylinder system for W-axis.

Vertical clamping jig.

Hydraulic system.

Pneumatic system.

Cutting fluid system.

3 colors working condition light.

LED work light.

Toolbox with tools.

MITSUBISHI control system.

Manual Pulse Generator (MPG).

Electric cabinet with air cooling system.

| Horizontal Milling Machine | ||

| MODEL NO. | NC-400i | |

| Machining capacity | Length of workpiece | 50 ~ 350 mm |

| Max. thickness of round tube | 3.2 ~ 6 mm | |

| Diameter of round tube | ф50 ~ 180 mm | |

| Travel & table | Travel of table Z-axis | 600 mm |

| Travel of head X/Y-axis | 180 mm | |

| Feed speed | Rapid feed speed Z-axis | 15 m/min |

| Rapid feed speed X/Y-axis | 15 m/min | |

| Cutting feed speed manual | 1 – 1500 mm/min | |

| Spindle | Spindle | NT50 equivalent |

| Dimension of spindle nose | ф 40 mm | |

| Spindle speed | 200 ~ 1600 RPM | |

| Vertical clamping | Vertical clamp hydraulic cylinder | ф 50 x 250 mm |

| Motor | Spindle motor output | 11 kW |

| Feed motor X,Y,Z-axis | 1.5 kW | |

| Control system | MITSUBISHI | |

| Others | Voltage | 220 V (Transformer) |

| Machine weight | 5 tons | |

| Machine size W x L x H (mm) | 2500 x 2600 x 2300 | |