L & W MACHINE TOOLS, INC.

Products

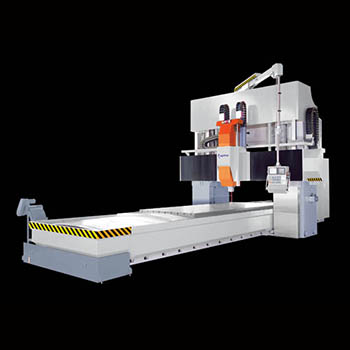

CNC VERTICAL TURNING CENTER

CNC VERTICAL TURNING CENTER

VTC series

Standard Accessories:

Hydraulic 3-jaw chuck for VTC-850

Table with manual 4-jaw chuck for VTC-1050~VTC-3000 series

Chip conveyor

Coolant system

Auto lubrication system

Complete splash guard

Work light

Warning light

Heat exchanger for electrical cabinet

Protection door

Manual for operation & maintenance

Manual for electrical & hydraulic circuit diagram

Tool holder base x 5pcs

Specification

| Model/Descriptions | Unit | VTC- 850ATC |

VTC- 850ATC+C |

VTC- 1050ATC |

VTC- 1050ATC+C |

VTC- 1200ATC |

VTC- 1200ATC+C |

VTC- 1600ATC |

VTC- 1600ATC+C |

|

| Capacity | Max. swing diameter | mm | 850 | 950 | 1200 | 1600 | ||||

| Max. turning diameter | mm | 760 | 900 | 1100 | 1600 | |||||

| Distance from ram to table | mm | 925 | 925 | 925 | 650-1450 | |||||

| Max. turning height | mm | 650 | 650 | 800 | 1250 | |||||

| Max. workpiece weight | kg | 1500 | 2000 | 3500 | 5000 | |||||

| Spindle | Table diameter (Manual chuck) |

mm | 533 | 800 | 1000 | 1250 | ||||

| Range of table speed |

rpm | 5-700 | 5-600 | 3-400 | 3-300 | |||||

| Change gear speed | 2-step | --- | 2-step | --- | 2-step | 2-step | ||||

| Spindle nose | mm | A2-11 | A2-11 | --- | --- | |||||

| Tool life spindle speed | --- | 50-2250 | --- | 50-2250 | --- | 50-2250 | --- | 50-2250 | ||

| ATC | ATC (Automatic tool change) |

12 | 12 | 12 | 16 | 12 | 16 | |||

| Tool Size | mm | □25, □32 | □25,□32 | □25,□32 | □25,□32 | |||||

| Cross-Section of Ram | mm | 200x 200 |

220x 220 |

200x 200 |

220x 220 |

200x 200 |

220x 220 |

220x 220 |

220x 220 |

|

| Feed | Rapid rate (X-Axis) | m/min | 10 | 10 | 10 | 10 | ||||

| Rapid rate (Z-Axis) | m/min | 10 | 10 | 10 | 10 | |||||

| Horizontal travel (X-Axis) | mm | -100+480 | -100+800 | -100+700 | -200+950 | |||||

| Vertical travel (Z-Axis) | mm | 600 | 600 | 600 | 900 | |||||

| Cutting feed rate | mm/rev | 0.001-500 | 0.001-500 | 0.001-500 | 0.001-500 | |||||

| Feed override | % | 0-150 | 0-150 | 0-150 | 0-150 | |||||

| Cross-rail travel | mm | Fixed | Fixed | Fixed | 800(200x4 step) | |||||

| CNC Controller System | Fanuc 0i-T | Fanuc 18i-T | Fanuc 0i-T | Fanuc 18i-T | Fanuc 0i-T | Fanuc 18i-T | Fanuc 0i-T | Fanuc 18i-T | ||

| Semens 802D | Semens 802D | Semens 802D | Semens 802D | |||||||

| Motors | Spindle motor (Cont. / 30min) |

kw | AC 18.5/22 | AC 18.5/22 | AC 30/37 | AC 37/45 | ||||

| Feed motor (X/Z axis) |

kw | 4.0 / 4.0 | 4.0 / 4.0 | 4.0 / 4.0 | 7.0 / 7.0 | |||||

| Live tool motor | kw | --- | AC 11/15 | --- | AC 11/15 | --- | AC 11/15 | --- | AC 11/15 | |

| Power requirement | kva | c | 55 | 40 | 55 | 75 | 90 | 75 | 90 | |

| Machine Size | Floor space (LxW) | mm | 2250 x 2700 | 2520 x 2800 | 4050 x 2900 | 4950 x 3200 | ||||

| Max. height (H) | mm | 3900 | 3900 | 3700 | 5000 | 5500 | ||||

| Net. Weight | kg | 12500 | 13500 | 15500 | 16300 | 24500 | 25300 | |||

| -L&W Machine Tools Inc. reserves the right to alter any mechanical specification without prior notice in the interests of product development. | ||||||||||