1YRS

KINIK COMPANY

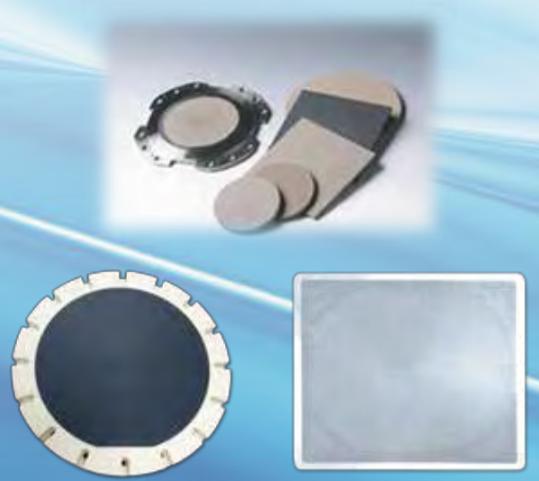

Products

Specification

Application

Wafer chuck for semiconductor dicing,grinding,washing…etc.

Features

-

Reusable

Reusable after rework. -

wear resistance

With the feature of extreme hardness of ceramics. -

No dust

Completely sintered, without dust. -

Light weight

With uniform pores, and light weight.

Brief introduction

Work Pieces can be adhesively fixed by aligning the porous to the body of the metal (or ceramic), and applying negative pressure from the back and sides of the body.

Due to the pores that are very tiny and averagely spread, vacuum chuck would not cause harms and scratch on your work pieces, improving the yield rate, making the best partner of manufacture.

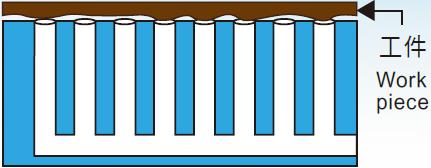

Basic porous structure

Cross-section of aluminum chuck table

With larger and limited pores, distortion of workpiece might occur.

Specifications

| Commonly used specification | |

|---|---|

| Pore diameter (μm) | 2~100 μm |

| Flatnes | 0.002 mm minimum (Customized) |

| Porosity (%) | 35~50 % |

| Surface Color | Black / White / Tawny |

| Shape | Round, Square, Cylindrical, Customized |

| Body materials | Stainless steel Aluminum Titanium alloy Ceramics |

| Size | Round (Φ5mm to Φ600mm, 6"~12") Square (50mm x 50mm ~ 1,000mm x 1,000mm) |

| Body surface processing | Fluorine resin processing Alumite processing Electroless nickel plating |