Products

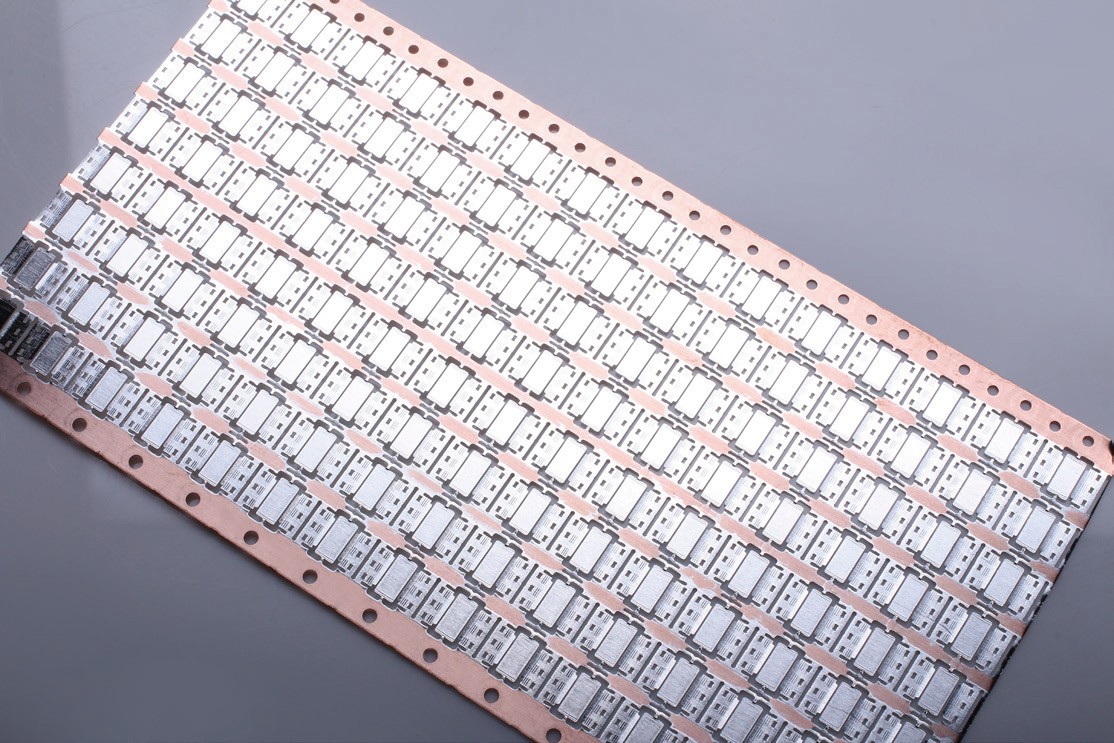

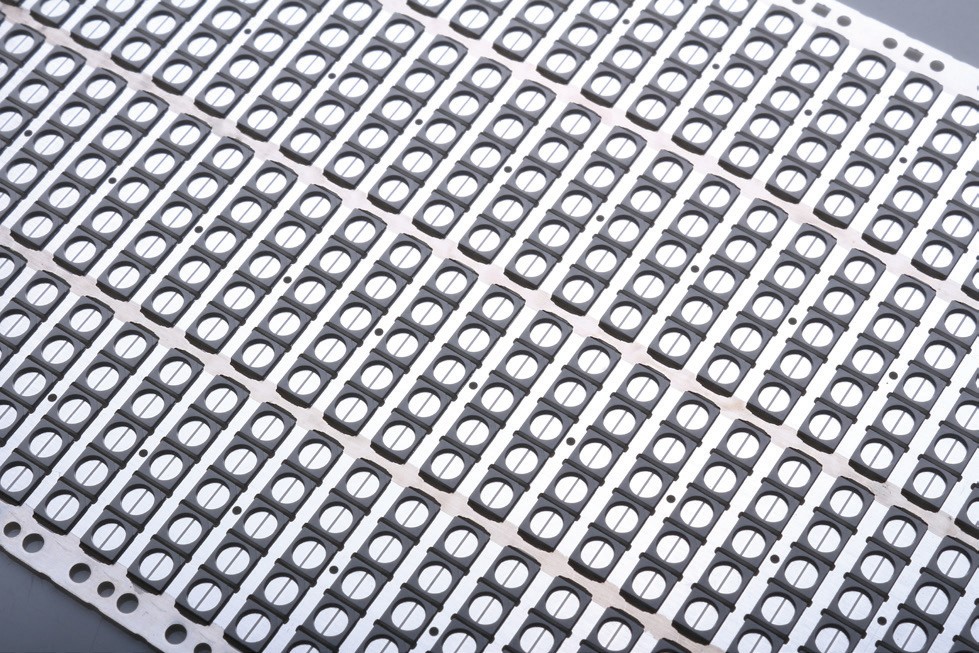

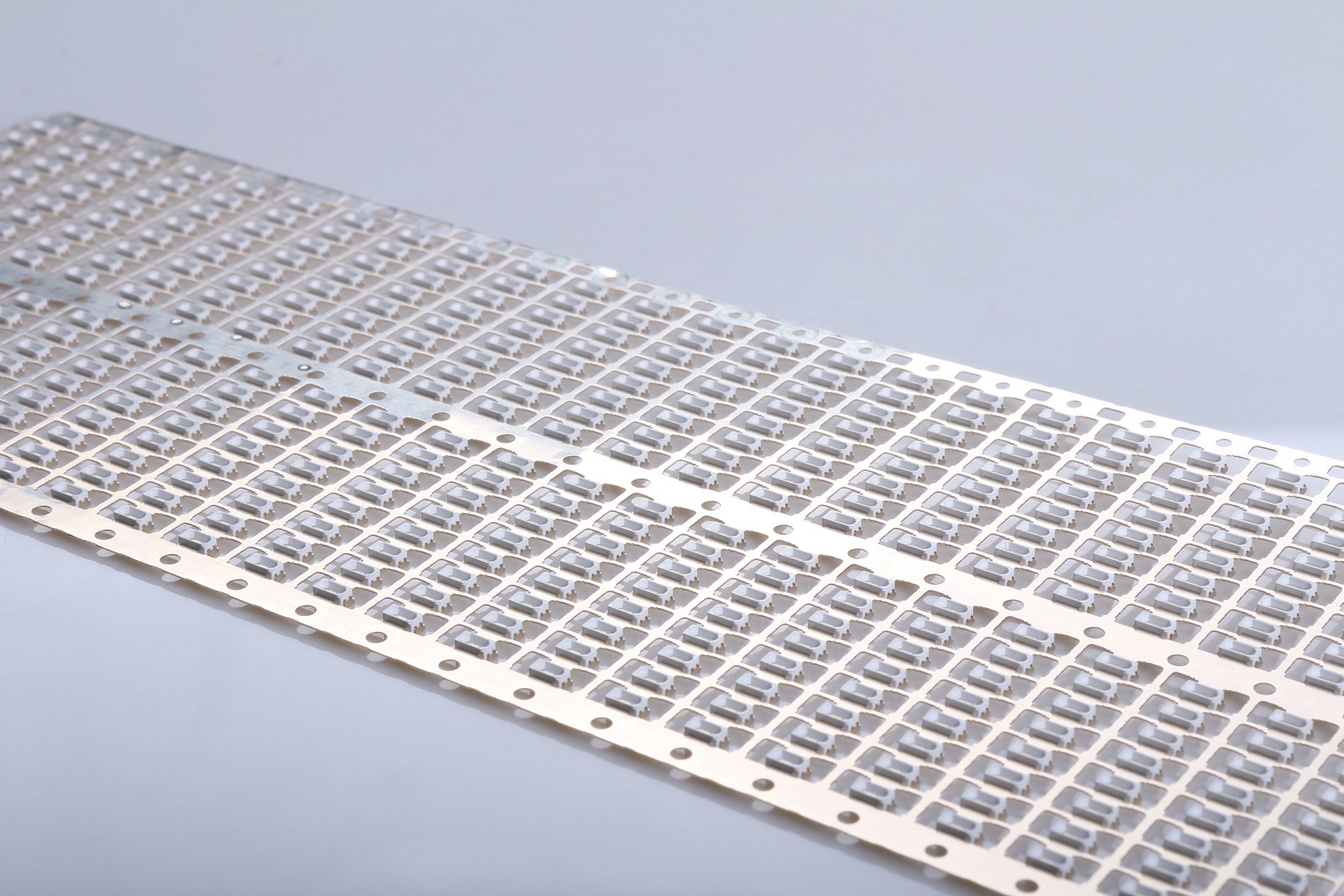

PPA (Polyphthalamide) and PCT (Polycyclohexylene Dimethylene Terephthalate) LED lead frames are specialized components used in LED (Light Emitting Diode) packaging. These materials are chosen for their high thermal stability and excellent mechanical properties, which are crucial for maintaining the performance and reliability of LED devices.

Key Characteristics:

Thermal Stability: PPA and PCT materials offer excellent heat resistance, which helps in managing the heat generated by LEDs and maintaining their performance.

Mechanical Strength: Both materials provide high mechanical strength and rigidity, ensuring that the lead frames can withstand the stresses during manufacturing and operation.

Dimensional Stability: PPA and PCT have low thermal expansion coefficients, which helps maintain the precise dimensions of the lead frames under varying temperatures.

Chemical Resistance: These materials exhibit good resistance to chemicals and environmental conditions, enhancing the durability of the lead frames.

Applications:

LED Packaging: PPA and PCT lead frames are used in the assembly of various types of LEDs, including surface-mount devices (SMD) and chip-on-board (COB) LEDs.

High-Performance Lighting: They are suitable for high-performance and high-power LED applications where efficient thermal management is critical.

Electronics: Used in a wide range of electronic devices that incorporate LED technology, including lighting fixtures, displays, and automotive lighting.

Manufacturing Process:

Design: Designing the lead frames to meet the specific requirements of the LED chip, including size, shape, and thermal properties.

Stamping: Using precision molds to stamp the PPA or PCT material into the desired shape.

Post-processing: Includes additional steps such as plating to improve electrical conductivity and enhance the performance of the lead frames.

Assembly: Integrating the lead frames with LED chips and performing quality checks to ensure reliability and performance.

Benefits:

Enhanced Heat Dissipation: Efficiently manages the heat generated by LEDs, contributing to longer operational life and improved performance.

Durability: High resistance to mechanical and environmental stress ensures long-term reliability of the LED components.

Precision: Maintains dimensional accuracy and stability, which is crucial for the precise operation of LEDs.