Products

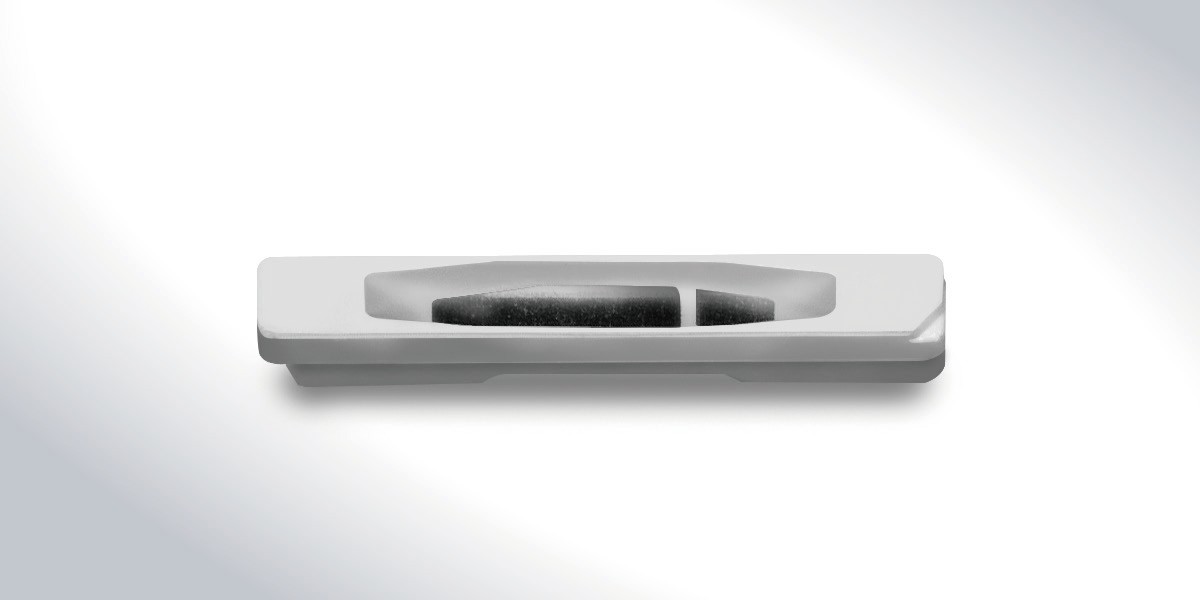

Transfer molded parts for variety components are specialized components created through the transfer molding process, which involves transferring a preheated polymer into a mold cavity to form diverse and functional parts used in various applications. This process is well-suited for producing high-precision, intricate parts across different industries.

Key Features:

Versatile Material Use: Transfer molding accommodates a wide range of materials, including high-performance polymers, enabling the production of parts with various mechanical, thermal, and chemical properties.

High Precision: This process allows for the creation of complex shapes and fine details, making it ideal for parts that require high accuracy and precision.

Enhanced Durability: Parts produced through transfer molding are designed to meet high durability standards, making them suitable for demanding environments and applications.

Manufacturing Process:

Design: Develop detailed designs for the components, specifying dimensions, shapes, and features required.

Material Preparation: Preheat the polymer material to the appropriate viscosity and temperature for transfer molding.

Mold Preparation: Prepare the molds, ensuring they are designed to accommodate the complex shapes and features of the components.

Transfer Molding: Transfer the preheated polymer into the mold cavity under pressure. The material fills the mold, taking the desired shape as it cools and solidifies.

Post-Processing: After molding, the parts undergo additional steps such as trimming, inspection, and functional testing to ensure they meet quality standards.

Applications:

Automotive Components: Used in various automotive parts including connectors, housings, and brackets that require durability and precision.

Electronics: Applied in electronic components such as connectors, terminals, and housings where high performance and reliability are essential.

Medical Devices: Utilized in medical device components like housings, connectors, and structural parts that need to meet stringent health and safety standards.

Industrial Equipment: Employed in industrial machinery and equipment components, including control panels and structural supports, where strength and precision are required.

Consumer Goods: Used in components for consumer products such as appliances, tools, and gadgets, providing both functionality and aesthetic appeal.

Advantages:

Complex Geometry: Transfer molding is well-suited for creating parts with complex shapes and detailed features.

Material Flexibility: A wide range of materials can be used, allowing for tailored properties based on application requirements.

Precision Manufacturing: High precision ensures that parts meet strict tolerances and performance specifications.

Cost Efficiency: The process can be cost-effective for high-volume production, reducing manufacturing costs and time.