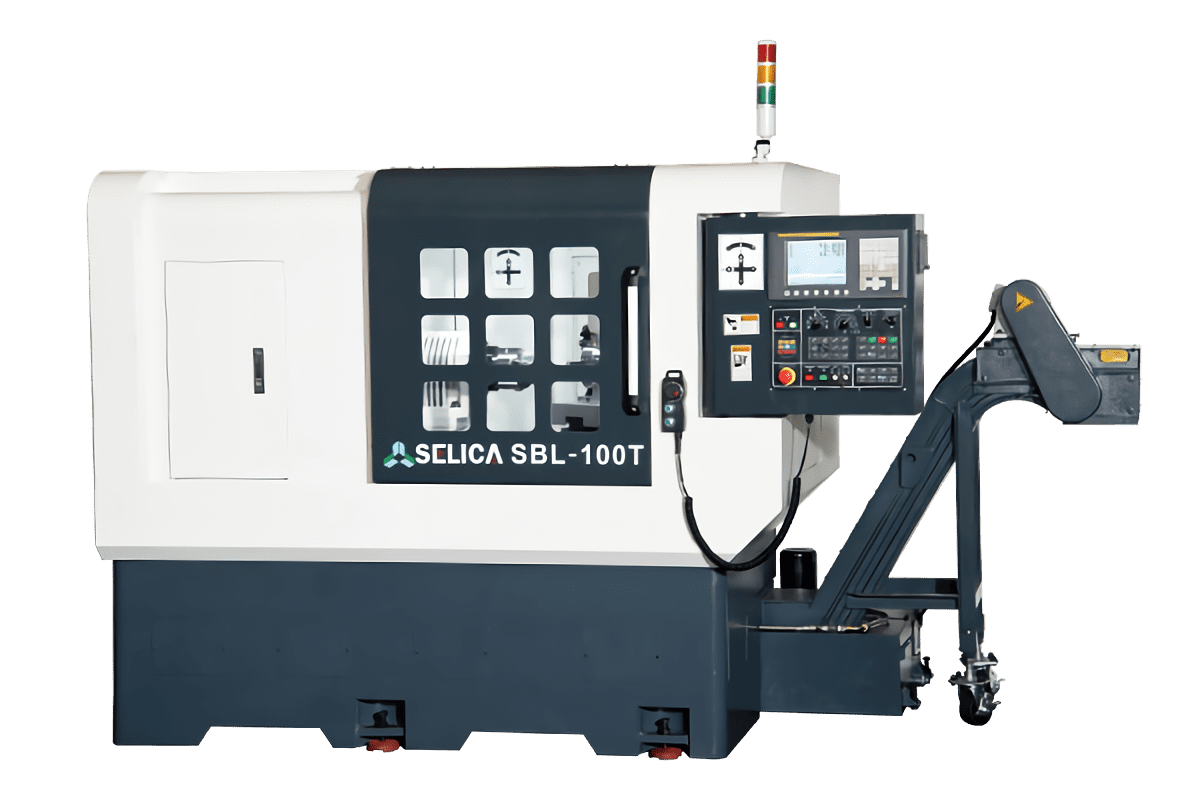

SELICA INTERNATIONAL CO., LTD.

產品介紹

Application: ball pin, ball joint machining, femoral head, inner ball joint, out ball joint, tie rod.

SBL series is designed for the ball head machining, which is the best solution for high quality sphere roundness and surface roughness.

SBL series includes rough turning, fine turning, diamond burnishing, part pulling, and cut-off process.

Feature

Application: ball joint machining, femoral head, inner ball joint, out ball joint, tie rod.

SBL series is designed for the ball head machining, which is the best solution for high quality sphere roundness and surface roughness.

SBL series includes rough turning, fine turning, diamond burnishing, part pulling, and cut-off process.

Burnishing process is ideal to enhance the surface hardness, extend the life-time and enlarge the allowance of abrasion.

About diversity of control axis, SBL series use B axis to do ball head machining and burnishing. B axis process the circular movement, so that the roundness can be achieved up to ±0.01mm. On the other hand, for traditional CNC lathe, the sphere machining is controlled by X and Y axis only, which lead to oval shape.

Except standard advantage of CNC controller, SBL series uses sliding heading spindle design and square guide way on Z axis movement, which ensure the accuracy and stability.

SBL series can equip with gang type tool (4-position), hydraulic turret (6-position) and power turret (8-position) to achieve multiple application.

Spindle Feature

Spindle motor equip BiI8/10000 (7.5kw), which hold heavy loading and stability while doing the burnishing process.

High-rigidity spindle and high-speed bearing support spindle speed up to 6000 rpm with high stability.

While machining special angle or using special tool, break plate support accurate position of spindle.

Belt type driver ensures powerful loading, steady performance and low cost of maintenance.

Materials

Worm gear : Special high-tensile aluminum-brass equal in strength to a steel alloy.

Worm shaft : Hardened alloy steel

High Rotation Torque

The combination of brass and alloy steel offers less friction. Motor torque is transferred efficiently. High class materisl worm system guarantees high torque transmission.

Large Worm Gear

The worm gear with a large pitch diameter creates a large engagement area and less pressure on the contact surface, resulting in resistance against wear.

| Model | Unit | SBL-100T | SBL-180T | SBL-250T |

| Swing over bed | mm | Ø350 | Ø500 | Ø520 |

| Max. turning diameter (ball head) | mm | Ø100 | Ø180 | Ø250 |

| Max. turning diameter (ball valve) | inch | Ø1/2"~2-1/2" | Ø2"~4.5" | Ø3"~6" |

| Spindle nose type | ASA | A2-4 | A2-5 | A2-6 |

| Spindle chuck type | 5C Collet Chuck 16C Collet Chuck(Opt.) 5" 3-Jaw Chuck (Opt.) |

16C Collet Chuck 6" 3 Jaw Chuck (Opt.) |

16C Collet Chuck 8" 3 Jaw Chuck (Opt.) |

|

| Spindle bore | mm | Ø45 | Ø56 | Ø62 |

| Spindle speed | rpm | 4000 (Std.) 6000 (Opt. ) |

3000 (Std.) 4500 (Opt. ) |

2000 (Std.) 4000 (Opt. ) |

| Spindle power | kw | 5.5kw (Std.) 7.5kw (Opt. ) |

7.5kw (Std.) 10kw (Opt. ) |

11kw (Std.) |

| X-axis motor power | kw | 1.2 | 1.2 | 1.8 |

| Z-axis motor power | kw | 1.8 | 2.5 | 2.5 |

| B-axis motor power | kw | 3 | 3 | 3 |

| X-axis travel | mm | 90 | 90 | 90 |

| Z-axis travel | mm | 90 | 90 | 90 |

| B-axis travel | degree | -60° / +95° | -60° / +95° | -60° / +95° |

| Z-axis rapid traverse rate | mm/min | 15000 | 15000 | 15000 |

| X-axis rapid traverse rate | mm/min | 15000 | 15000 | 15000 |

| B-axis rapid traverse rate | mm/min | 6000 | 6000 | 6000 |

| Number of tool station | T | 6 (Hydraulic turret) | 6 (Hydraulic turret) | 6 (Hydraulic turret) |

| Tool size | mm | 20x20 | 20x20 | 20x20 |

| Machine dimensions (LxWxH) | m | 2.5x1.9x1.8 | 2.8x2.2x1.9 | 3.1x2.3x1.9 |

| Voltage | 220V/60HZ/3P | 220V/60HZ/3P | 220V/60HZ/3P | |

| Power requirement | kva | 20 | 25 | 28 |

| Weight | kg | 3000 | 3300 | 3800 |

Standard Accessories |

Optional Accessories |

| ● Collet chuck | ● Spindle motor upgrade |

| ● Hydraulic cylinder | ● Spindle speed upgrade |

| ● Hydraulic turret 6 position | ● X axis extend to 150 mm |

| ● Power unit | ● Z axis extend to 150 mm (for long part) |

| ● Pneumatic system unit | ● Upgrade to hydraulic servo turret (8T) |

| ● Full guard | ● Upgrade to servo power turret (8T) with C axis |

| ● Machine base | ● C axis air breaking system |

| ● Heat exchanger | ● 16C collet chuck and collet (work piece diameter less than Ø40 mm) |

| ● Automatic lubrication system | ● Extention nose collet type chuck and collet (ball valve) with orientation pin |

| ● Three color warning light | ● 3 jaw chuck |

| ● Working lamp | ● Chuck air blow |

| ● Coolant system | ● Burnish diamond tool holder and tool |

| ● Tool and tool box | ● Burnish diamond tool |

| ● Wedge block | ● Chip conveyor and cart |

| ● Leveling bolts and blocks | ● Transformer |

| ● Operation manual | ● Voltage Stabilizer |

| ● Machine voltage: 220VAC / 60HZ / 3 phase |

● CE mark |