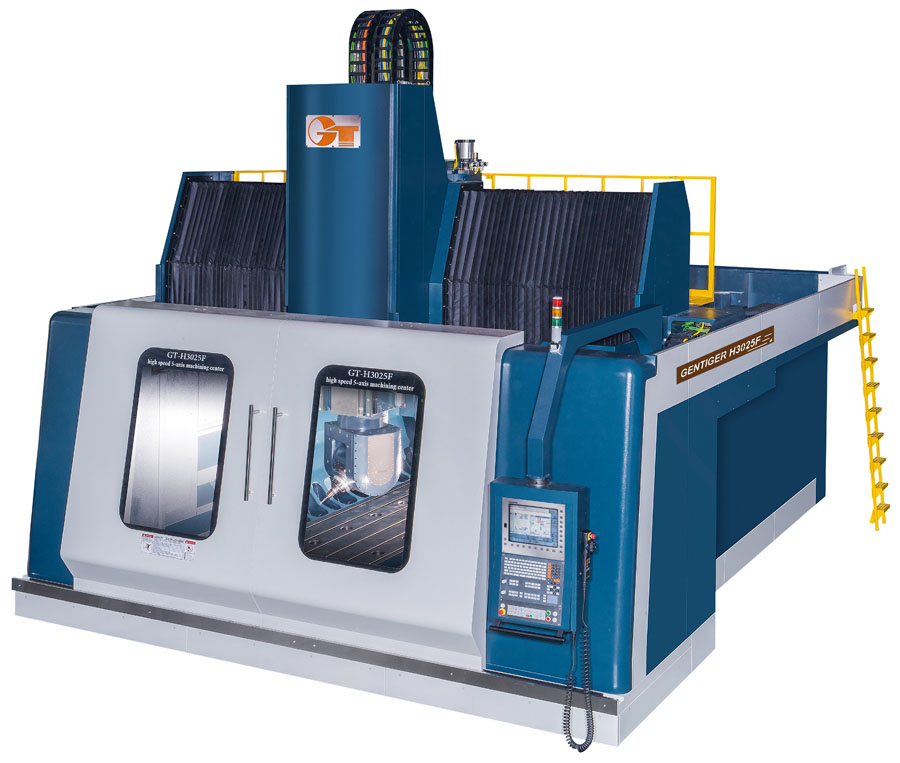

GENTIGER MACHINERY INDUSTRIAL CO., LTD.

Products

High speed 3-axis machining center

High speed 3-axis machining center GT-H3025

GT-H3025

Feature

The gantry type structure is designed specifically for 5 Axis high speed machining.

With 5 axes simultaneously machining intricately shaped parts can be machined with only one setup.

Trapezoid type cross beam dramatically increases loading capacity.

Highly rigid “L” shaped double side-wall features optimal force-flow distribution.

Equipped with Germany made swiveling head to guarantee the highest accuracy.

18,000rpm, HSK-A63 built-in type spindle.

X, Z axis are driven by twin servo systems.

Roller type linear guide ways on X, Y, Z axis.

Positioning accuracy: 0.003mm/ 300mm.(ISO-230-2)

Repeatability accuracy: ±0.003mm.(ISO-230-2)

Specification

Specification

| MODEL | GT-H3025F(5 Axis) | GT-H3025(3 Axis) |

| Travel (X, Y, Z) | 3000 x 2250 x 1200 mm | |

| Table area | 2425 x 3000 mm | |

| Max. Spindle speed | 18000 RPM | 24000 RPM |

| Spindle Type | Built-in | |

| Spindle taper | HSK-A63 | |

| ATC capacity | 24T/ Opt. 120T | |

| B Axis | |

| Rated Torque | 382 Nm |

| Maximum Torque | 575 Nm |

| Clamping Torque at P Max | 2160 Nm |

| Clamping Torque at Po | 1200 Nm |

| Clamping Method | Pnematic |

| Swiveling Angle | ±105∘ |

| Positioning Accuracy | ±5 sec |

| C Axis | |

| Rated Torque | 810 Nm |

| Maximum Torque | 1100 Nm |

| Clamping Torque at P Max | 1680 Nm |

| Clamping Torque at Po | 930 Nm |

| Clamping Method | Pnematic |

| Swiveling Angle | ±200∘ |

| Positioning Accuracy | ±3 sec |

STANDARD ACCESSORIES

STANDARD ACCESSORIES

- Coolant system

- Work lamp

- Tool box

- Spindle air blow system

- Chip air blow device

- Air conditioner for electrical cabinet

- M.P.G

- Work end indication lamp

- Semi-enclosed splash guard

- Central control lubricator

- Operation and maintenance manual

- Leveling bolts and pads

- Ethernet support function

- Spindle thermal growth compensation function

- X,Y,Z axes optical scales

- Chain type chip conveyor

OPTIONAL ACCESSORIES

OPTIONAL ACCESSORIES

- Oil skimmer

- Automatic tool length measurement (GT-H3025F 5 axis STD.)

- Automatic workpiece measurement (GT-H3025F 5 axis STD.)

- Coolant through spindle

- Transformer

- Chain type tool magazine