Products

Feature

Outstanding Features

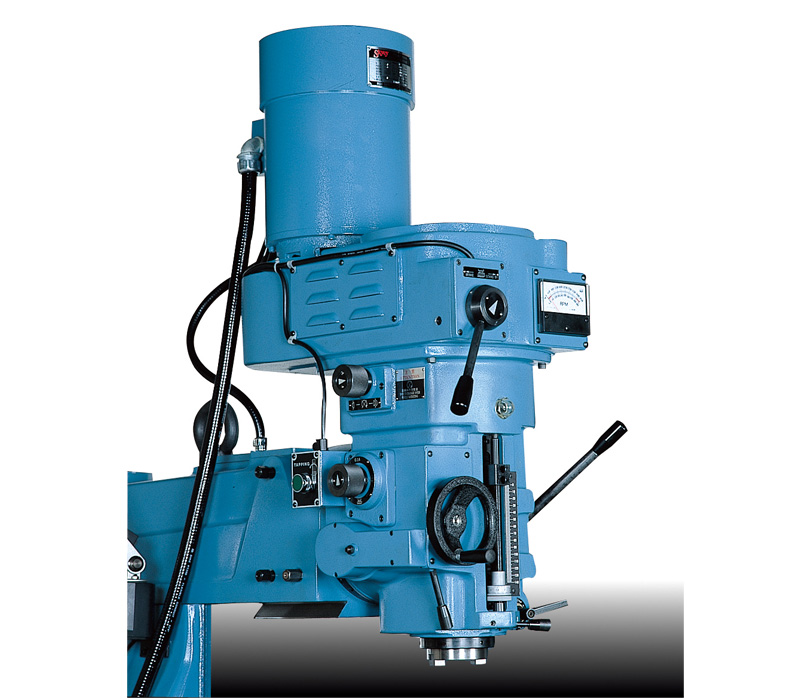

Ruggedly built turret type milling head.

The spindle is one piece machined from SCM-21 alloy steel, carburized, tempered and precision ground. The spindle runs on high precision P4 class bearing.

Fitted with forced lubrication system for gears, clutch, and bearings inside the milling head for low noise running and long service life of head parts.

The milling head can be swivelled 45° to the right and left. It is quickly locked and loosened by double screws and clamping ring.

Constructed of high quality castings FC-30 and Fcd-35, rib reinforced, tempered, and stress relieved for maximum rigidity without deformation.

The table is manufactured from high quality cast iron FC-30. The table surface and slideways are tempered, high frequency hardened, and precision ground. The T-slots are precision machined. The 6 surfaces on 3 T-slots are precision ground to within 0.01mm accuracy in full way, permitting for fast milling operations.

The X, Y axis feeds are driven by high precision C5 class preloaded double nut ball screws with tightening function, providing smooth feed, minimum backlash, and superior positioning accuracy.

The X-axis feed is driven by a 1000W AC servo motor and the original driver, incorporated with a magnetic clutch for safe, powerful, fast, stable and quiet traverse. Automatic feed speed range is 0 – 1500 mm/min. Rapid feed speed as high as 3500mm/min.

An installation space is left for a Y-axis servo motor, providing convenient fitting at any time (OPTIONAL EQUIPMENT)

The X, Y axis slideways, dovetailed surfaces and gibs are coated with Turcite-B, precision scraped for long term accuracy and maximum wear resistance.

Precision chip wipers protect the x, Y and Z axis ways for scratch free traverse.

The digitally displayed, timer controlled lubricator provides automatic lubrication to the X, Y, Z axis slideways, feed screws, gears and bearings. The oil supply time and lubrication interval can be set. An oil manifold ensures uniform lubrication to the parts.

Specification

| MODEL | SHCM-S96RVS |

| Spindle speeds | 60~3600 RPM VARIABLE SPEED (MAX.4050 RPM) |

| Spindle nose taper | NST 40 |

| Head tilt (R & L) | 45° (R & L) |

| Overarm travel | 410 MM |

| Quill travel | 140 MM |

| Distance from spindle nose to table | 0~530 MM |

| Distance from spindle center to column | 170~580 MM |

| Automatic spindle feed speed | 0.035/0.07/0.14 MM (PER REV.) |

| Table area | 1250 x 280 MM |

| Longitudinal travel | 750 MM |

| Gross travel | 400 MM |

| Vertical travel | 440 MM |

| T-slot (Width x No. x Distance) | 16 x 3 x 65 MM |

| Automatic lougitudinal travel | 0-1500 mm/min |

| Quick lougitudinal travel | 3500 mm/min |

| Quick vertical travel | 1150 MM |

| Spindle | 3.7 KW (5HP) VARIABLE SPEED MOTOR |

| Knee | 0.75 KW (1HP) |

| Lubrication pump | 75 W |

| Magnetic pump | 13 W |

| Machine dimensions | 1900 x 2260 x 2305 MM |

| Packing dimensions | 1460 x 1920 x 2030 MM |

| N.W. | 2160 KG |

| G.W. | 2320 KG |

STANDARD ACCESSORIES

STANDARD ACCESSORIES

- Service tools

- Tool box

- Front and rear chip guard

- Cooling system

- Halogen work lamp

OPTIONAL ACCESSORIES

OPTIONAL ACCESSORIES

- Spindle feed depth gauge

- Y axis servo driver

- Spindle tapping device

- Riser block 100mm

- Digital readout