QUICK JET MACHINE CO., LTD.

Products

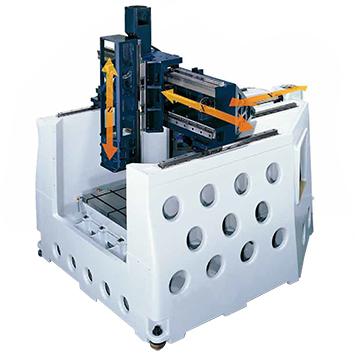

CNC 5Axis Gantry Machining Center

CNC 5Axis Gantry Machining Center AV-95X

AV-95X

●The GTV-95X is a 5-axis simultaneous control machining center that can adjust the cutting efficiency and quality by tilting the tool as its best cutting edge, without central of tool contact. ●The GTV-95X optimally concentrate the machining process for multiface, intricately shaped ●3-axis program still can run under constant position setting for A,C axis. (Without any cutting interference)

Specification

■HIGH TECHNOLOGY OF 5-AXIS MILLING MACHINING CENTER

- The GTV-95X is a 5-axis simultaneous control machining center that can adjust the cutting efficiency and quality by tilting the tool as its best cutting edge, without central of tool contact.

- The GTV-95X optimally concentrate the machining process for multiface, intricately shaped parts, and some difficult position of workpiece where 3-axis can't overcome, such as under cut.

- Facilitates muliface machining in one chuck to reduce setup work, fixture making and improve the effciency.

- For depth mould, GTV-95X still can keep high efficiency machining by setting a suitable angle of tool, shorten the length of tool holding.

- Avoiding accumulative error from series machining procedures, decreasing total cutting time thar substantially achieve the request : High Speed, High Accuracy, High Efficiency.

|

TRAVEL

|

||

|

X axis (Spindle left/right)

|

900 mm

|

|

|

Y axis (Table in/out)

|

600 mm

|

|

|

Z axis (Spindle vertical)

|

480 mm

|

|

|

Spindle nose to table surface (min/max)

|

0-480 mm

|

|

|

XYZ drive protection

|

torque limit coupler direct

|

|

|

TABLE

|

||

|

Size

|

ø500 mm

|

|

|

T-slot (W x No. x P)

|

14 x 8 mm

|

|

|

Table type

|

A、C axis

|

|

|

Max. table load (evenly distributed)

|

500 Kg

|

|

|

A axis ration

|

+30°~ -120°

|

|

|

C axis ration

|

0°~ 360°

|

|

|

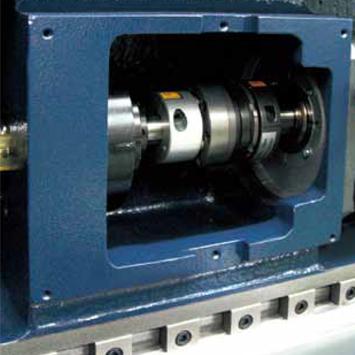

SPINDLE (builtin-in)

|

||

|

Spindle speed

|

24,000 min

|

|

|

Motor

|

29 kW

|

|

|

Tool taper

|

HSK-A63

|

|

|

Bearing dia.(I.D.)

|

ø 70 mm

|

|

|

Oil chiller temp. control

|

±2°C of machine body temperature

|

|

|

FEEDRATES

|

||

|

Cutting feed

|

X/Y 1-20,000 mm/min, Z 1-12,000 mm/min

|

|

|

X/Y/Z rapid traverse

|

X/Y 20,000 mm/min, Z 12,000 mm/min

|

|

|

A rapid axis feedrate

|

6.25 rpm

|

|

|

C rapid axis feedrate

|

12.5 rpm

|

|

|

X/Y/Z axis servo motor

|

4.7 / 8.7 / 4.7 kW

|

|

|

AXES

|

||

|

X/Y/Z axis linear guideway

|

55×2 / 55×2,45×2 / 45×2 mm

|

|

|

X/Y/Z axis linear ballscrew dia.

|

Ø50 / 50 / 40 mm

|

|

|

ACCURACY

|

||

|

Linear axis position accuracy

|

0.004 mm (ISO 230/2)

|

|

|

Linear axis repeatability

|

<0.002 mm (ISO 230/2)

|

|

|

|

linear scale

|

without linear scale

|

|

Rotating axis position accuracy (sec)

|

C:8” / A:15”

|

C:15” / A:45”

|

|

Rotating axis repeatability (sec)

|

C:±2.5” / A: ±2.5”

|

C: ±3” / A: ±4”

|

|

AUTOMATIC TOOL CHANGER (Disk magazine)

|

||

|

Max. tool dia.

|

Ø30 mm

|

|

|

Max. tool length

|

220 mm

|

|

|

Max. tool weight

|

7kg

|

|

|

Tool storage capacity

|

20 tools

|

|

|

AIR SUPPLY

|

||

|

Pressure / Consumption

|

6 kg/c㎡ / 500 l /min

|

|

|

POWER SUPPLY

|

||

|

Capacity

|

40 KVA

|

|

|

COOLANT

|

||

|

Coolant pump

|

2 sets , 0.58 kW ea.

|

|

|

Coolant tank capacity

|

90 L

|

|

|

MACHINE

|

||

|

Machine dimension (LxWxH)

|

3,010 x 3,716 x 3,100 mm

|

|

|

Machine weight

|

12375 kg

|

|