Products

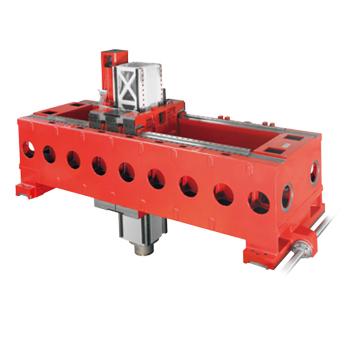

●The beam is a box type symmetrical structure and deployed with 4 ways with great span. the spindle head is built in the beam. the specially designed "Box-in-Box" symmetrical structure reduces influence by environmental temperature variation to a minimum. ●The base and table are one-piece fabricated with high loading-resistant capability. three axis movements are not affected by work piece weight, which results in high machining accuracy and quality. ●The X-axis is driven by double servo systems in combination with the use of double linear scales for feedback control, that ensure smooth movements and permit dynamic accuracy to be fully controlled. ●Coolant through ball screws on three axis combined with rigid assembling enable the machine to achieve higher positioning accuracy and repeatability. ●Three axis are equipped with torque-limited couplings allowing for setting safe torque. This provides a safety protection for transmission system by avoiding the risk of overload. ●Compact construction. Great machining capacity. Small space occupation.

| TRAVEL | X axis (spindle in / out) | 2,500 mm | |

| Y aixs (spindle left / right) | 1,600 mm | ||

| Z axis (spindle vertival) | 800 mm | ||

| Spindle nose to table surface(min/max) | HSK-A100,350-1150 mm | HSK-A100,650-1450mm | |

| HSK-A63 SC,383-1183 mm | HSK-A63 SC,683-1483 mm | ||

| X/Y/Z axis drive protection | Direct torque limit coupler | ||

| TABLE | Size | 2,650x1,950 mm | |

| T-slot ( W x No. x P) | 22 x 7 x 285 mm | ||

| Table type | Fixed | ||

| SPINDLE (builit-in) | Spindle speed | HSK-A100-14,000 / 10,000 rpm | HSK-A63,SC-24,000 rpm |

| Motor | 32 kW | 29 Kw | |

| Spindle taper | HSK-A100 | HSK-A63 | |

| Oil chiller | ±1℃ of amibient shop temperature | ||

| FEED RATES | Cutting feed | 1-24,000 mm/min | |

| X/Y/Z axis rapid traverse | 24,000 mm/min | ||

| THREE AXIS | X/Y/Z axis servo motors | 9.9x2 / 9.9 / 7.2kW | |

| X/Y/Z axis linear ways | 55x2 / 55x4 /45x4 mm | ||

| X/Y/Z axis ball screws | Ø63 x2 / Ø63 / Ø50 | ||

|

AUTOMATIC TOOL CHANGER (Disk Magazine) |

Max. tool Dia. | HSK-A100,Ø80 | HSK-A63 SC,Ø35 |

| Max. tool length | 350 mm | 220 mm | |

| Max. tool weight | 12 kg | 7 kg | |

| Tool storage capacity | 16Tools | 20 Tools | |

| PRECISION | Positioning accuracy ( X/Y/Z) | 0.006 mm ( ISO 230/2) | |

| Repeatability (X/Y/Z) | <0.004 mm (ISO 230/2) | ||

| AIR SUPPLY | Pressure / Consumption | 6 kg/cm2 /500 l /min | |

| POWER SUPPLY | Capacity | 71 KVA | |

| COOLANT | Coolant pump | 2 sets, 0.58 Kw ea. | |

| Coolant tank capacity | 400 L | ||

| MACHINE SIZE | Machine dimension (LxWxH) | 5,340 x 5,035 x 4,283 mm | 5,340 x 5,035 x 4,583 mm |

| Machine weight | 30,000 kg | 33,000 kg | |