Products

Features:

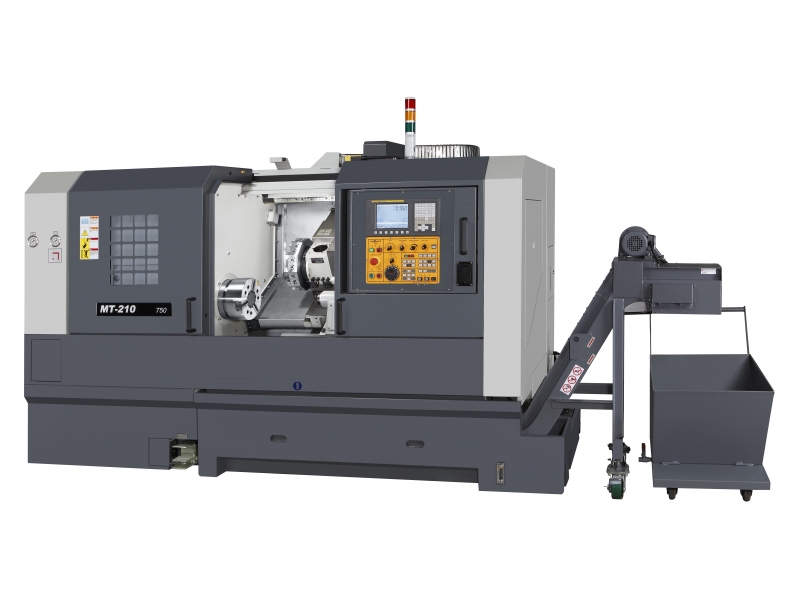

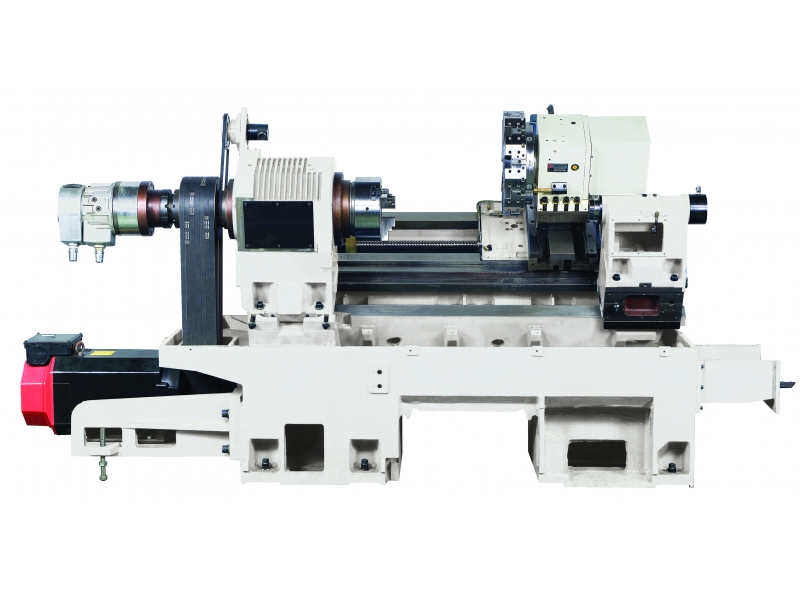

30 degree slant bed design for easy operation and easy chip removal

Cast iron bed with optimally designed ribs with integral stiffness provides an very strong rigidity

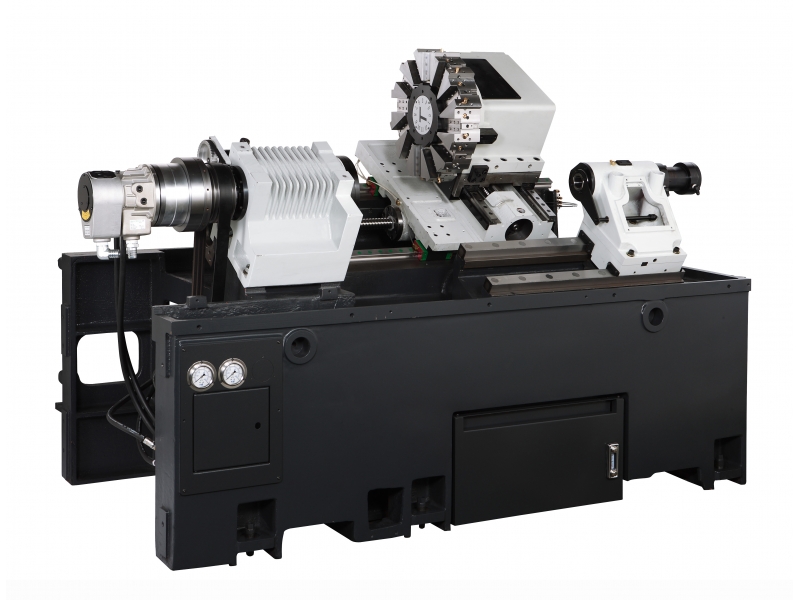

Big diameter bearing provides high rigidity

High-resolution encoder mounted on spindle to provide accurate C axis positioning

C axis with continuous indexing

Double supported ball screws direct-driven servo motors are used for axial movements

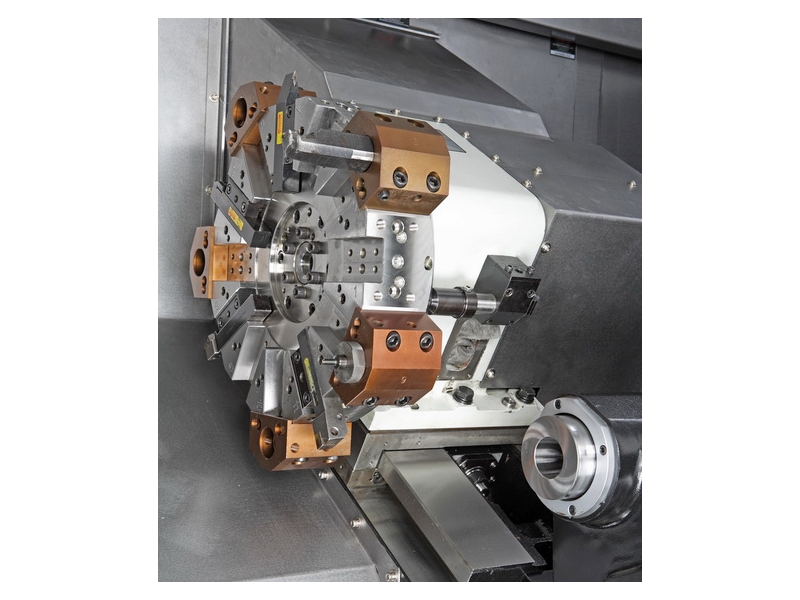

Servo turret or hydraulic turret is offered for users as an alternative choice

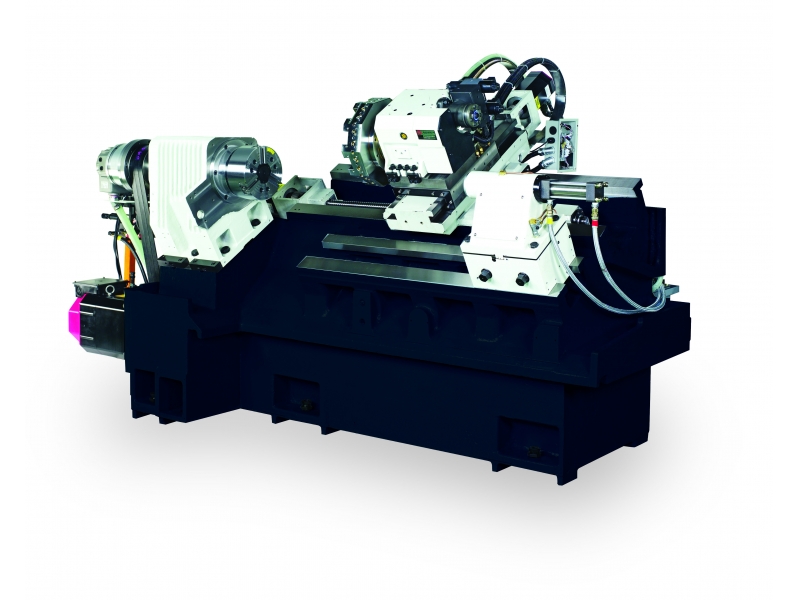

Large disc is equipped for easy tool set up

Special spindle motor location design reduces machine floor space

One-piece structure on the machine structure to provide massive rigidity

Programmable tailstock available as an option

Large coolant tank

Internal coolant supply through turret disc

High pressure pump

PLC controlled chip conveyor

* Besides MT-800, there are various other models;

Click the pictures above or here to our official website to see more.

| MODEL | MT-208 |

|---|---|

| Machine type | Linear (Box) |

| Machine body type | Slant |

| Swing over bed | 560 mm |

| Standard turning dia | 350 mm |

| Max. turning dia | 350 mm |

| Max. turning length | 500 / 750 mm |

| Bar capacity | 52 mm |

| X-axis stroke | 380 mm |

| Z-axis stroke | 530 / 780 mm |

| Spindle speed | 4000 rpm |

| Spindle nose | A2-6 |

| Spindle thru-hole dia | 65 mm |

| Spindle bearing inside dia | 100 mm |

| Type of turret | 12 |

| Height of square tool | 25 mm |

| Dia of boring bar holder | 40 mm |

| 3-jaw Chuck | 8" |

| Stroke of tailstock | 350 / 500 mm |

| Tail sleeve dia | 85 mm |

| Taper of tailstock | MT #5 |

| Tail sleeve stroke | 100 mm |

| Rapid feed speed | X:20 / Z:24 m/min (opt.:30 for Linear) |

| Spindle motor | 11 / 15 kW |

| Lubricating oil motor | 1.5 kW |

| Cutting oil motor | 0.55 kW |

| Servo turret motor | 1.2 kW |

| Electric power | 30 KVA |

| Hydraulic pressure | 50 L |

| Lubricating oil | 1.8 L |

| Cutting oil | 160 L |

| Floor space (L x W) | 2300 / 3100 x 1500 mm |

| Net weight | 4350 / 4850 kg |

| Standard Accessories | Optional Accessories | ||

|---|---|---|---|

| ◆ 3-jaw hydraulic chuck | ◆ Bar feeder | ||

| ◆ Hydraulic system | ◆ Parts catcher | ||

| ◆ Hydraulic tailstock | ◆ Tool setter | ||

| ◆ Live center | ◆ C-axis | ||

| ◆ Coolant system | ◆ VDI turret | ||

| ◆ Morse taper sleeve | ◆ VDI tool holders | ||

| ◆ Auto lubrication system | ◆ Auto door | ||

| ◆ Working light | ◆ Chip conveyor | ||

| ◆ Heat exchanger for electrical cabinet | ◆ Chip bucket | ||

| ◆ Soft jaw | ◆ Transformer | ||

| ◆ Foot switch for chuck clamp | ◆ CE mark | ||

| ◆ MPG handwheel | ◆ Safety torque limit clutch | ||

| ◆ Operation & maintenance manuals | ◆ Hoisting hook package | ||

| ◆ Tools and box | ◆ Levelling kit | ||

| ◆ Leveling bolts and screws | ◆ Bar feeder interface (LNS system) | ||

| ◆ OD tool holder | ◆ Additional tool holders and sleeves | ||

| ◆ Facing tool holder | ◆ SIEMENS controller | ||

| ◆ Boring bar holder & sleeves | |||

| ◆ Drill sleeves | |||

| ◆ FANUC controller | |||