TAIWAN YUN LIN ELECTRONIC CO., LTD.

Products

High Voltage Isolation Tubing

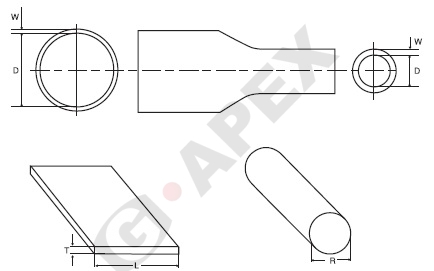

HB1 - Heat Shrinkable Busbar Insulation Tubing

HB1

Applications:

HB1 is suitable for the application in busbar insulation up to 3.6kV. The multiple color options are convenient for the application in busbar color distinction. With the properties of flexibility, excellent mechanical and UV resistance, it is easy to process on straight or bent busbars, providing safe and reliable long-term protection for covered products.

Approvals / Specifications:

IEC60060-1

Operating temperature range :

Continuous operating temperature: -55˚C~125˚C

Minimum shrink temperature: 70˚C

Full recovery temperature: Above 110˚C

COLOR:

black

white

red

blue

yellow

green

Standard colors: black, white, red, blue, yellow, and green

Specification

Characteristics

- Shrinkable Ratio:2:1

- Corrosion resistance and flame retardant

- Excellent chemical resistance and insulation performance

- Red, yellow, blue, green, white and black for color distinction.

Specification

| Part Number | Nominal Size(mm) | busbar dimension | As supplied (mm) | After recovered (mm) | Applicable busbar dimension (mm) |

Standard Length (Meter) |

||

|---|---|---|---|---|---|---|---|---|

| I.D.(min) (D) |

I.D.(max) (d) |

W.T. (w) |

L+T (min)(max) | R(min)(max) | ||||

| HB1-020 | 20 | 20x3 | 20 | 10 | 0.80±0.15 | 19~24 | 12.0~15.0 | 100 |

| HB1-030 | 30 | 30x3 30x4 | 30 | 15 | 0.90±0.15 | 27~39 | 17.0~25.0 | 50 |

| HB1-040 | 40 | 30x10 40x4 | 40 | 20 | 1.00±0.15 | 36~47 | 23.0~30.0 | 50 |

| HB1-050 | 50 | 40x10 50x5 50x6 |

50 | 25 | 1.00±0.15 | 44~68 | 28.0~43.0 | 25 |

| HB1-060 | 60 | 50x8 50x10 60x6 60x8 |

60 | 30 | 1.55±0.20 | 52~86 | 33.0~55.0 | 25 |

| HB1-070 | 70 | 60x10 | 70 | 35 | 1.60±0.25 | 60~102 | 38.0~65.0 | 25 |

| HB1-080 | 80 | 60x10 80x10 | 80 | 40 | 1.70±0.25 | 68~118 | 43.0~75.0 | 25 |

| HB1-090 | 90 | 100x10 | 90 | 45 | 1.70±0.25 | 75~129 | 48.0~82.0 | 25 |

| HB1-100 | 100 | 100x8 100x10 100x12 |

100 | 50 | 1.80±0.30 | 86~141 | 55.0~90.0 | 25 |

| HB1-120 | 120 | 100x15 120x10 120x12 120x15 |

120 | 60 | 1.90±0.30 | 104~172 | 66.0~110.0 | 15 |

| HB1-150 | 150 | 150x12 150x15 | 150 | 75 | 1.90±0.30 | MAX | 15 | |

| HB1-180 | 180 | 150x10 150x20 | 180 | 90 | 2.10±0.30 | MAX | 15 | |

Technical Data

| Property | Specification Requirement |

Test Method | Typical Value |

|---|---|---|---|

| Longitudinal change | -10%~10% | ASTM D2671 | Pass |

| Tensile strength | ≥10.3Mpa | ASTM D2671 | ≥11.3Mpa |

| Tensile strength after aging | 70% of initial value | ASTM D2671 (158˚C/168 hrs) |

≥80% |

| Elongation at break | ≥200% | ASTM D2671 | ≥400% |

| Elongation at break after aging | ≥100% | ASTM D2671 (158˚C/168 hrs) |

≥200% |

| Low temperature flexibility | No cracking | ASTM D2671 (-30˚C/1 hr) |

No cracking |

| Volume resistivity | ≥1014Ω.cm | ASTM D2671 | ≥1014Ω.cm |

| Dielectric voltage withstand | AC2500V/60S No breakdown |

ASTM D2671 | No breakdown |

| Flammability | VW-1 | UL224 | Pass |