Products

Features

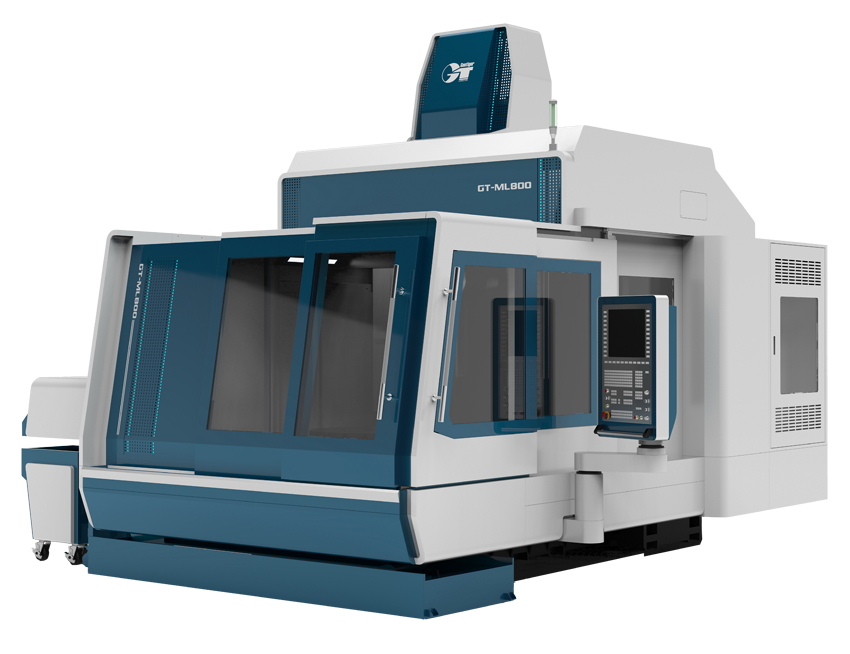

.The closed type double column structure is excellent for 5 axis high speed machining, presenting optimal structure stability.

.Equipped with a vertical horizontal milling head (A axis) is combined with the rotary table (C axis) to perform turning and milling operations.

.The 45° vertical horizontal swiveling head is applicable for both vertical and horizontal machining, increasing flexibility in machining applications.

.With 5 axis simultaneous machinging, intricately shaped parts can be machined with only one setup.

.Equipped with a direct drive high precision rotary table with 5 seconds of positioning accuracy and 2 seconds of repeatability accuracy.

.Y axis is mounted with 3 linear guideways for increased stability during cutting.

.X/Y/Z axis are all equipped with linear scales, providing closed loop control and ensuring higher positioning accuracy.

.Chain type tool magazine, equipped with arm type tool change, providing fast tool change, smooth and stable motions.

Specification

| MODEL | ML800 | |

| Travel (X, Y, Z) | 1000 x 1000 x 1000 mm | |

| Table area | Ø800 mm | |

| Max. Spindle speed | 14000 RPM | |

| Spindle Type | Built in | |

| Spindle taper | HSK-T63 | |

| ATC capacity | 40 | |

STANDARD ACCESSORIES

STANDARD ACCESSORIES

- Coolant tank

- Work lamp

- Tool box

- Coolant system

- Spindle air blow system

- Air conditioner for electrical cabinet

- MPG

- M30 work end indication light

- Spindle heat compensation system

- Caterpillar chip conveyor and cart

- Central control lubricator

- Operation and maintenance manual

- Leveling bolts and pads

- Chip augers at both sides of table

- Internet function

- X/Y/Z axis optical scales

- Complex tool length measurement device

- Auto workpiece measurement device

OPTIONAL ACCESSORIES

OPTIONAL ACCESSORIES

- Oil skimmer

- Oil fumes extraction

- Coolant through spindle