Products

Wave springs are especially suitable for applications requiring weight reduction and those constrained by a small installation space. Typical fields of use include: aerospace, precision machinery, hydraulic seals, and high-end motors.

Features:

1. The wave spring has the advantage of space saving (can reduce the working height by 50%) and can be used to replace the coil spring.

2. It has the same load and deformation as the ordinary helical compression spring. 3. The wave spring is suitable for radial and axial space.

4. Axial load can be transferred 100%

Types of wave springs:

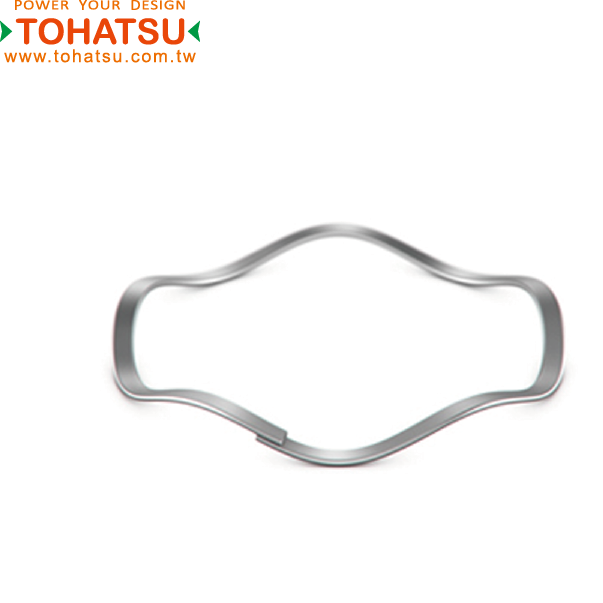

1. Single layer wave spring.

Main uses: 1. Used to provide preload and compensate assembly tolerances. 2. By clinging to the hole, the radial space is saved.

2. The top wave spring.

Main uses: 1. Compared with traditional coil springs, it saves 50% assembly space. 2. Has higher compression than single-layer wave coils.

Note for use: 1. Avoid the vibration of the bearing system during operation, which may easily cause damage to the wave spring.

Define requirements for spring design:

1. The use space usually refers to the working position of the wave spring in the hole or on the shaft. The distance between the bearing surfaces of the wave spring determines the axial actuation space or working height.

2. The load of the wave spring is generated by the working height and axial force of the spring itself. Some applications require two or more working heights, which must be listed as a design focus, especially when there are tolerances caused by stacking, it is a good solution to take the minimum load and maximum load as a design consideration Program.

3. High temperature applications, dynamic applications (fatigue), corrosive substances or other special application environments and conditions must be included in the evaluation. For a variety of different use environments, the best way is to choose the most ideal raw materials and stress, so that the spring can play the best role.

The traditional notch type and interface type wave springs are widely used in various fields due to the characteristics of small deformation and medium and low force values, which make them have precise and reliable functions.

Notched type is a gap left between the two ends of the spring

The interface type is that the ends overlap slightly.

The special design of the notch and the interface allows the two ends to move freely along the circumference when the spring is compressed and the outer diameter expands.

Therefore, these two types of wave springs can allow radial expansion in the installation space without the binding and breaking of traditional stamped washers.

For example, place a notched wave spring in a hole with a 0.5mm gap on each side and a distance of 0.25mm on each side between the inner diameter and the shaft.

When a wave spring is compressed, both its outer and inner diameters expand until the outer diameter contacts the bore wall.

Under the continuous force and deformation, the two ends of the wave spring notch will move and approach each other.

The interface-type wave spring also operates in a similar cyclical manner.

Material: Stainless Steel (17-7 PH/C)

|

品號

Product No.

|

適用孔徑

Applicable aperture

|

適用軸徑

Applicable shaft diameter

|

荷重(N)

load

|

工作高度

working height

|

自由長

Free length

|

波數

Wavenumber

|

彈性係數(N/mm)

Elasticity coefficient

|

|---|---|---|---|---|---|---|---|

| TSSB-0035-S17 | 9 | 6.86 | 25 | 1 | 1.5 | 3 | 52 |

| TSSB-0039-S17 | 10 | 7.49 | 27 | 1 | 1.57 | 3 | 48 |

| TSSB-0043-S17 | 11 | 8.46 | 29 | 1 | 1.83 | 3 | 35 |

| TSSB-0047-S17 | 12 | 9.17 | 33 | 1 | 1.57 | 3 | 59 |

| TSSB-0051-S17 | 13 | 9.53 | 38 | 1 | 1.57 | 3 | 66 |

| TSSB-0063-S17 | 16 | 11.28 | 44.5 | 1.57 | 2.29 | 3 | 65 |

| TSSB-0075-S17 | 19 | 14.28 | 53.4 | 1.57 | 3.05 | 3 | 35 |

| TSSB-0087-S17 | 22 | 16.46 | 62.3 | 1.57 | 2.79 | 3 | 48 |

| TSSB-0095-S17 | 24 | 18.46 | 66.7 | 1.57 | 3.56 | 3 | 35 |

| TSSB-0102-S17 | 26 | 18.22 | 71.2 | 1.98 | 2.54 | 3 | 111 |

| TSSB-0110-S17 | 28 | 20.22 | 75.6 | 1.98 | 2.79 | 3 | 85 |

| TSSB-0118-S17 | 30 | 22.22 | 84.5 | 1.98 | 3.3 | 3 | 66 |

| TSSB-0126-S17 | 32 | 24.22 | 89 | 1.98 | 3.81 | 3 | 52 |

| TSSB-0138-S17 | 35 | 27.22 | 97.9 | 1.98 | 4.57 | 3 | 38 |

| TSSB-0146-S17 | 37 | 28.72 | 102.3 | 1.98 | 3.81 | 3 | 58 |

| TSSB-0158-S17 | 40 | 31.72 | 111.2 | 1.98 | 5.08 | 3 | 37 |

| TSSB-0165-S17 | 42 | 33.72 | 115.7 | 1.98 | 3.05 | 4 | 99 |

| TSSB-0185-S17 | 47 | 38.72 | 129 | 1.98 | 3.81 | 4 | 68 |

| TSSB-0205-S17 | 52 | 43.11 | 142.4 | 2.36 | 3.56 | 4 | 121 |

| TSSB-0217-S17 | 55 | 46.11 | 151.3 | 2.36 | 3.81 | 4 | 100 |

| TSSB-0244-S17 | 62 | 51.69 | 169.1 | 2.36 | 4.32 | 4 | 85 |

| TSSB-0268-S17 | 68 | 57.17 | 186.9 | 2.77 | 4.32 | 4 | 131 |

| TSSB-0276-S17 | 70 | 59.17 | 191.3 | 2.77 | 4.32 | 4 | 119 |

| TSSB-0284-S17 | 72 | 61.17 | 195.8 | 2.77 | 4.57 | 4 | 108 |

| TSSB-0295-S17 | 75 | 64.17 | 204.7 | 2.77 | 5.08 | 4 | 94 |

| TSSB-0315-S17 | 80 | 68.66 | 218 | 2.77 | 5.59 | 4 | 76 |

| TSSB-0335-S17 | 85 | 71.38 | 231.4 | 2.77 | 5.59 | 4 | 83 |

| TSSB-0354-S17 | 90 | 76.38 | 249.2 | 2.77 | 6.35 | 4 | 68 |

| TSSB-0374-S17 | 95 | 81.38 | 262.5 | 2.77 | 7.37 | 4 | 57 |